For a job like this, the solution is a dust collector. Dust collectors enhance air quality by separating dust and other impurities from air or gas. There are four main types of dust collectors. One of these is the wet dust collector, also called the wet dust scrubber. Read More…

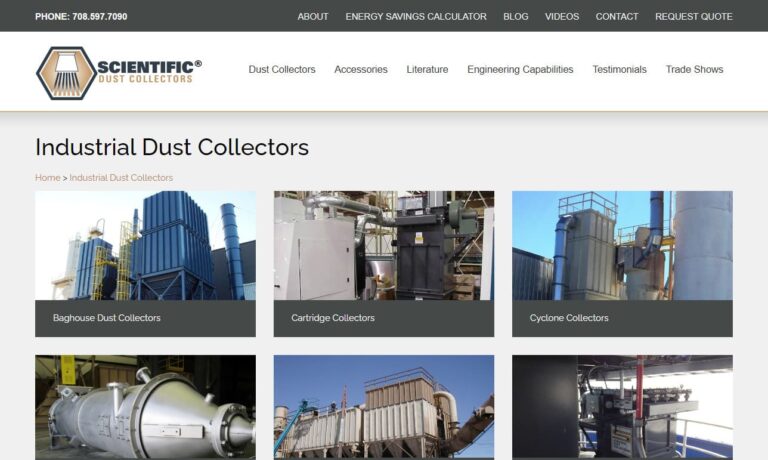

Since 1981, Scientific Dust Collectors has provided solutions for dust collecting, indoor air quality, separation equipment, and more. Our team of engineers has the capability to assist in the design of a dust collecting system and ducting that best fits your workplace. Design, engineering, and sales support are all done in one location at our Alsip, IL facility. Our goal is to give customers the ...

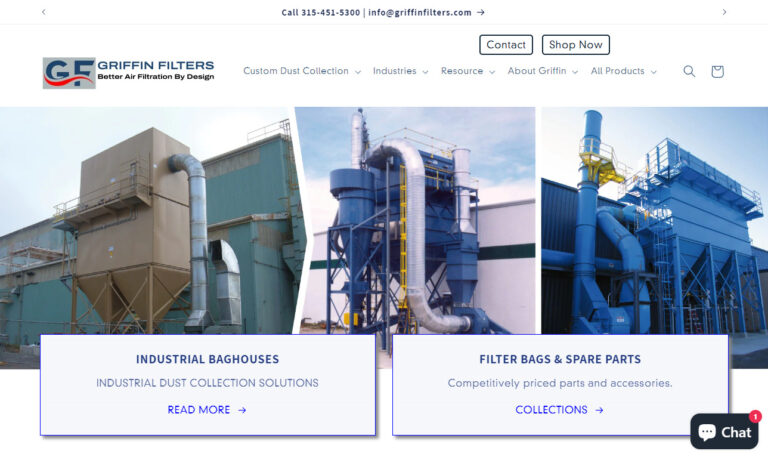

Griffin Filters is a trusted and dedicated leading manufacturer in the dust collector industry. We offer a wide selection of dust collectors with customization options available in order to serve various industries. Our experts are committed to manufacturing high-quality dust collectors that fit our customers' needs at competitive prices. Since its start in 1950, Griffin Filters has been setting...

Ever since our inception in 1989, Robovent has been a leader in the manufacturing and design of ventilation and filtration systems. We have experience coming up with solutions to protect our customers from a wide range of dust, including aluminum dust, cast iron grinding dust, fertilizer dust, and more. Industries we serve include automotive, military, construction, medical, and aerospace. For a...

Our world-class facilities set us apart from the competition. We work hard to make our customers happy with our air filters. We can provide what you need to keep your air clean in whatever industry you are in. Our goal is to exceed your expectations so you can focus on what you do best! Whether you need support in design, products, delivery, or support, we can supply it all!

Environmental Clean Air Company provides clean air solutions for a wide variety of indoor air quality problems. We offer a wide selection of dust collectors, mist collectors, welding booths, work containment booths, cyclones, electrostatic filters, air cleaning and filtration equipment to meet the demands of today's Industry.

At Coral USA Innovative Air Solutions , we are committed to delivering high-performance dust collection systems that enhance workplace safety, improve air quality, and ensure compliance with industry regulations. With extensive experience in air filtration and dust control, we design and manufacture advanced dust collectors that effectively capture and remove airborne contaminants, providing...

Our dust collecting systems are designed to eliminate respirable airborne contaminants from the work environment. We believe that eliminating airborne contamination in the workspace can lead to better employee performance.

More Wet Dust Collector Manufacturers

Wet Dust Collectors: Comprehensive Guide to Industrial Dust Collection Solutions

Wet dust collectors are advanced air pollution control systems designed to remove airborne dust and fine particulates from industrial processes by using a liquid—most commonly water—to separate, capture, and neutralize hazardous contaminants. These systems are essential for maintaining safe, compliant, and efficient workplaces across a broad spectrum of industries, including woodworking, food processing, metalworking, foundries, pharmaceuticals, plastics manufacturing, building restoration, and more.

How Wet Dust Collectors Work

The fundamental principle behind wet dust collection is the utilization of water or another scrubbing liquid to agglomerate dust particles, which are then removed from the airstream. Wet dust collectors, also known as wet scrubbers or wet filtration systems, operate in one of three core configurations:

- Gas-Humidification: Increasing the humidity of the gas stream to promote the aggregation of particulate matter.

- Gas-Liquid Contact: Forcing the contaminated air to interact with water droplets through processes such as inertial impaction, interception, diffusion, or condensation nucleation.

- Gas-Liquid Separation: Separating the now wet and heavy particulate matter from the air stream after contact.

After dust collection with a wet system, the "cleaned" or "scrubbed" exhaust gases are typically passed through a demister or mist eliminator to remove entrained water droplets. This ensures that the air released back into the environment is free from both dust and excess moisture, supporting compliance with OSHA, EPA, and NFPA regulations. The contaminated water—now containing the absorbed dust particles—is then either processed for reuse within the system or discharged after proper treatment.

Post-Collection Processing: Water and Sludge Management

Effective wet dust collection systems incorporate efficient water and sludge management solutions to maintain continuous operation and prevent secondary pollution. Dust-laden water is routed to a clarification unit or a drag tank chain system. A clarification unit separates solids from the liquid, while a drag tank chain removes settled sludge, transporting it for disposal in a dumpster or stockpile. Proper management of this sludge is critical for regulatory compliance and environmental stewardship.

Types of Wet Dust Collectors: Pressure Drop Classifications

Wet dust collectors are categorized based on their pressure drop—a key factor influencing their energy consumption, efficiency, and suitability for different particulate sizes and concentrations. Understanding these classifications helps facility managers, safety engineers, and purchasing agents select the optimal solution for their specific industrial dust control needs. The primary categories are:

- Low-Energy Collectors: 0.5 to 2.5 inches water gauge (124.4 to 621.9 Pa)

- Low-to-Medium Energy Collectors: 2.5 to 6 inches water gauge (0.622 to 1.493 kPa)

- Medium-to-High Energy Collectors: 6 to 15 inches water gauge (1.493 to 3.731 kPa)

- High-Energy Collectors: Greater than 15 inches water gauge (greater than 3.731 kPa)

The pressure drop directly correlates with the collector's ability to capture smaller particulates and handle varying dust loads. Higher energy collectors are more effective for sub-micron dust control, while lower energy systems offer efficiency for larger particle sizes and less demanding applications.

Popular Wet Dust Collector Designs and Their Applications

Gravity-Spray-Power Scrubbers

A prominent example within low-energy wet dust collectors, the gravity-spray-power scrubber uses atomized liquid droplets generated by spray nozzles. As the contaminated airstream passes upward through the chamber, these droplets fall downward, colliding with dust particles and causing them to agglomerate and settle out. The dirty water drains at the bottom of the scrubber, where it can be further treated or recycled.

- Approximately 70% efficiency for particles 10 µm and larger

- Ideal for processes with high dust concentrations that might clog dry collectors

- Best suited for applications where sub-10 µm particle removal is not critical

Wet Cyclone Dust Collectors

A key example of low-to-medium energy wet dust collectors is the wet cyclone. These systems harness centrifugal force to spin dust-laden air at high velocities, propelling particulates toward the wetted walls of the cyclone chamber. Water introduced from the top washes captured dust down, preventing re-entrainment and ensuring effective particulate removal.

- Efficient for particles 5 µm and above

- Resistant to clogging, making them suitable for sticky, fibrous, or high-moisture dusts

- Often used as pre-cleaners in multi-stage dust control systems

Venturi Scrubbers

Venturi scrubbers represent a class of medium-to-high and high-energy wet dust collectors. In a venturi scrubber, the contaminated gas stream is accelerated through a constricted throat, where it meets high-velocity water sprays. This intense turbulence promotes maximum contact between dust particles and water droplets, resulting in exceptional particulate capture—even for sub-micron and hazardous dusts.

- Extremely high collection efficiencies (up to 99% for fine particles)

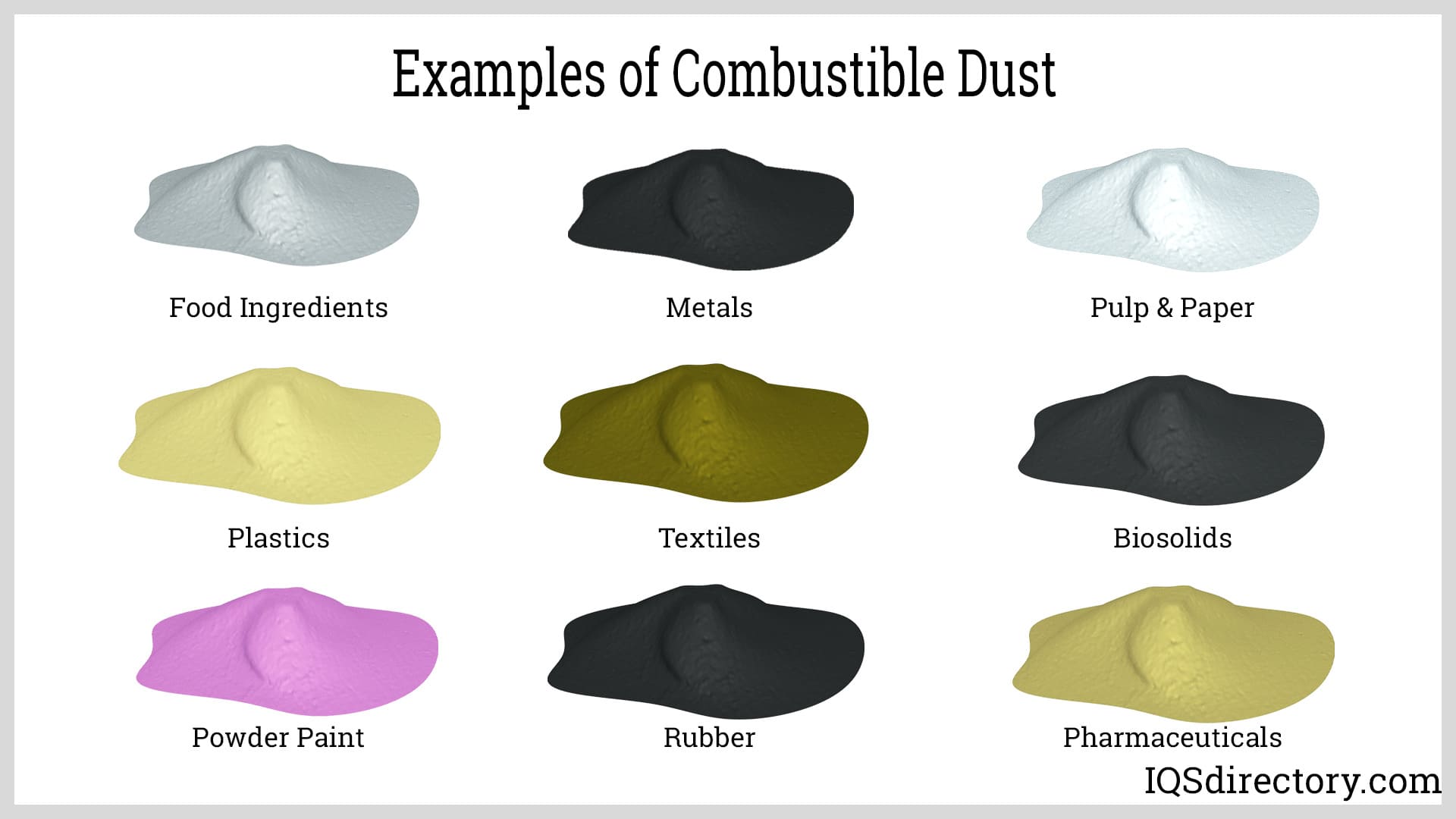

- Suitable for toxic, explosive, or combustible dusts (such as metal fines, pharmaceuticals, or chemical powders)

- Commonly used in foundries, metalworking, specialty chemical manufacturing, and battery recycling

Packed Bed Scrubbers

Packed bed wet scrubbers use a tower filled with packing material to maximize the contact area between the incoming gas stream and the scrubbing liquid. As air flows upward and water trickles downward, dust and gaseous contaminants are absorbed or neutralized. These systems are often customized for targeted removal of both particulate and gaseous pollutants.

- Effective for simultaneous control of dust and acid gases (such as HCl or SO2)

- Ideal for chemical processing, laboratory exhaust, and pharmaceutical production facilities

- Can be combined with other filtration or abatement technologies for enhanced performance

Industries and Applications: Where Are Wet Dust Collectors Used?

Wet dust collectors play a crucial role in a wide range of industrial and commercial environments. Their unique advantages make them the preferred choice for applications where dry dust collectors may struggle—such as handling sticky, explosive, or water-reactive dusts, or when spark and fire risks must be minimized. Some of the most common applications include:

- Woodworking and sawmills (sanding, sawing, planing)

- Food processing (grain handling, sugar refining, spice milling)

- Foundries and metal casting (removal of metal dust and fumes)

- Battery manufacturing and recycling (lead, cadmium, lithium dusts)

- Pharmaceutical and nutraceutical production (powder blending, tableting)

- Composite and plastics fabrication (resin and fiberglass dust control)

- Chemical manufacturing (acid gas and particle removal)

- Building restoration and concrete cutting (silica dust abatement)

Benefits of Wet Dust Collection Systems

When selecting an industrial dust collection solution, understanding the benefits of wet dust collectors versus alternative systems such as cartridge dust collectors, baghouse filters, or electrostatic precipitators is essential. Key advantages of wet dust collectors include:

- Superior Explosion and Fire Control: By saturating dust particles, wet collectors greatly reduce the risk of explosion and fire, making them ideal for combustible or reactive dusts (e.g., aluminum, magnesium, titanium, flour, sugar).

- Effective for Sticky and Hygroscopic Dusts: Wet systems excel at capturing sticky, fibrous, or hygroscopic materials that can clog dry filters.

- Multi-Pollutant Removal: Some designs (e.g., packed bed scrubbers) can simultaneously remove both particulate matter and harmful gases or vapors.

- Minimal Maintenance Downtime: Automated sludge removal and water recycling options reduce manual intervention compared to many dry systems.

- Flexible Configuration: Available in portable, modular, and custom-engineered forms to fit virtually any process or plant layout.

- Regulatory Compliance: Help meet stringent air quality, health, and safety standards set by OSHA, EPA, and NFPA.

Decision Factors: How to Select the Right Wet Dust Collector

Choosing the optimal wet dust collection system for your facility requires careful analysis of several critical factors. Facility managers, engineers, and operations teams should consider:

- Nature of the Dust: Is it combustible, toxic, sticky, or corrosive? What is the particle size distribution?

- Airflow Volume and Dust Loading: What are the required airflow rates (CFM) and the expected dust concentrations?

- Required Removal Efficiency: What particle size and removal rate is necessary to meet compliance?

- Maintenance and Operational Constraints: Is there a preference for automated cleaning or minimal downtime?

- Water Management: Are there restrictions or special requirements for water use, discharge, or recycling?

- Space and Layout: What are the available footprint and integration needs with existing process equipment?

- Budget and Lifecycle Costs: How do initial investment, energy consumption, and maintenance compare with alternative solutions?

Need expert guidance? Compare leading wet dust collector manufacturers and suppliers to request quotes, evaluate technical capabilities, and receive application-specific recommendations.

Common User Questions About Wet Dust Collectors

- What are the maintenance requirements for wet dust collectors?

Maintenance typically involves periodic inspection and cleaning of spray nozzles, water sumps, and demisters, as well as monitoring sludge removal systems. Automated options can greatly reduce manual labor. - Are wet dust collectors suitable for combustible dust?

Yes. Wet collectors are widely used for safe capture of combustible and explosive dusts, as the water medium suppresses ignition sources and spark propagation. - How do wet and dry dust collectors compare?

Wet collectors are superior for sticky, fibrous, or explosive dusts, while dry collectors (such as baghouses or cartridge filters) may be preferable for dry, free-flowing dusts or where water use is restricted. - Do wet dust collectors require water treatment?

The recirculated water often needs filtration and/or chemical treatment to prevent odor, corrosion, or scaling. Discharged water must be treated per local environmental regulations. - Can wet dust collectors control both particulate and gas-phase pollutants?

Certain designs (e.g., packed bed scrubbers) are engineered for dual-phase pollutant removal, making them versatile air pollution control solutions.

Latest Innovations and Trends in Wet Dust Collection

Advancements in wet dust collector design continue to improve efficiency, sustainability, and cost-effectiveness. Current trends include:

- Smart Monitoring and Automation: Integration with IoT-enabled sensors for real-time performance tracking, predictive maintenance, and remote diagnostics.

- Energy-Efficient Designs: Lower pressure drop systems, variable frequency drives (VFDs), and optimized spray patterns to reduce energy and water consumption.

- Enhanced Water Recycling: Closed-loop water management and advanced filtration technologies to minimize waste and operating costs.

- Modular, Scalable Solutions: Pre-engineered modules that can be rapidly deployed or expanded as process demands change.

- Compliance-Driven Engineering: Systems designed to exceed OSHA, NFPA, and EPA standards for hazardous dusts, including explosion isolation and containment features.

Ready to Improve Your Facility’s Air Quality?

If you are searching for the best wet dust collector for your industrial process, consider your application’s unique challenges and regulatory requirements. Wet dust collectors offer a proven, reliable solution for controlling hazardous dusts, improving worker safety, and maintaining compliance. To explore specific product options, compare technical specifications, or connect with trusted manufacturers, request a quote from leading dust collection companies today.

Explore Related Topics

- What are the advantages of cyclone dust collectors?

- How do I choose the right industrial dust collection system?

- Compare dust collection equipment manufacturers

- Frequently asked questions about dust collection

Looking for more information on wet dust collector applications, sizing, pricing, or installation? Contact an expert today and get customized advice for your facility’s dust control needs.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services