Portable dust collectors are essential tools used to maintain a clean and healthy working environment. These devices are designed to capture and filter harmful particles produced during various industrial processes. A portable dust collector is a versatile and convenient alternative to stationary models, which are typically larger and not as easy to move around. These portable devices are commonly used in woodworking, metalworking, and construction sites, among others. Read More…

Since 1981, Scientific Dust Collectors has provided solutions for dust collecting, indoor air quality, separation equipment, and more. Our team of engineers has the capability to assist in the design of a dust collecting system and ducting that best fits your workplace. Design, engineering, and sales support are all done in one location at our Alsip, IL facility. Our goal is to give customers the ...

Griffin Filters is a trusted and dedicated leading manufacturer in the dust collector industry. We offer a wide selection of dust collectors with customization options available in order to serve various industries. Our experts are committed to manufacturing high-quality dust collectors that fit our customers' needs at competitive prices. Since its start in 1950, Griffin Filters has been setting...

Ever since our inception in 1989, Robovent has been a leader in the manufacturing and design of ventilation and filtration systems. We have experience coming up with solutions to protect our customers from a wide range of dust, including aluminum dust, cast iron grinding dust, fertilizer dust, and more. Industries we serve include automotive, military, construction, medical, and aerospace. For a...

Our world-class facilities set us apart from the competition. We work hard to make our customers happy with our air filters. We can provide what you need to keep your air clean in whatever industry you are in. Our goal is to exceed your expectations so you can focus on what you do best! Whether you need support in design, products, delivery, or support, we can supply it all!

Environmental Clean Air Company provides clean air solutions for a wide variety of indoor air quality problems. We offer a wide selection of dust collectors, mist collectors, welding booths, work containment booths, cyclones, electrostatic filters, air cleaning and filtration equipment to meet the demands of today's Industry.

At Coral USA Innovative Air Solutions , we are committed to delivering high-performance dust collection systems that enhance workplace safety, improve air quality, and ensure compliance with industry regulations. With extensive experience in air filtration and dust control, we design and manufacture advanced dust collectors that effectively capture and remove airborne contaminants, providing...

Our dust collecting systems are designed to eliminate respirable airborne contaminants from the work environment. We believe that eliminating airborne contamination in the workspace can lead to better employee performance.

More Portable Dust Collector Manufacturers

Components of Portable Dust Collectors

A portable dust collector comprises several essential components that work together to ensure its efficient operation. These include a blower that generates suction, a filter that captures the particles, a dust collection bag that holds the captured material, and a dust collection hose that connects the different parts. Additionally, a cyclone separator can be installed to enhance the machine's performance by removing larger debris before it reaches the filter.

Differences from Other Dust Collectors

What sets portable dust collectors apart from other types of dust collectors is their design and components. Portable models are typically smaller in size and designed to be more compact for easy transportation. Moreover, they are equipped with smaller motors, which consume less power, making them more suitable for on-site work. Although their capacity is limited compared to stationary models, they are more affordable and versatile, making them ideal for use in smaller workspaces.

Considerations Regarding Portable Dust Collectors

One of the considerations regarding portable dust collectors is their limited capacity. As a result, they are not suitable for use in large workshops or for heavy-duty tasks. Additionally, they require regular maintenance to ensure their optimum performance, which can be time-consuming and labor-intensive. They are also less efficient than stationary models, as they generate lower suction and are less effective at capturing finer particles.

Benefits of Portable Dust Collectors

Despite their limitations, portable dust collectors offer several benefits over other types of dust collectors. They are versatile and can be used for various applications, making them a convenient choice for contractors and DIY enthusiasts alike. They are also more affordable and consume less power, making them an economical choice for smaller workshops. Furthermore, they help maintain a safe and healthy work environment by capturing harmful particles that can cause respiratory issues.

Applications of Portable Dust Collectors

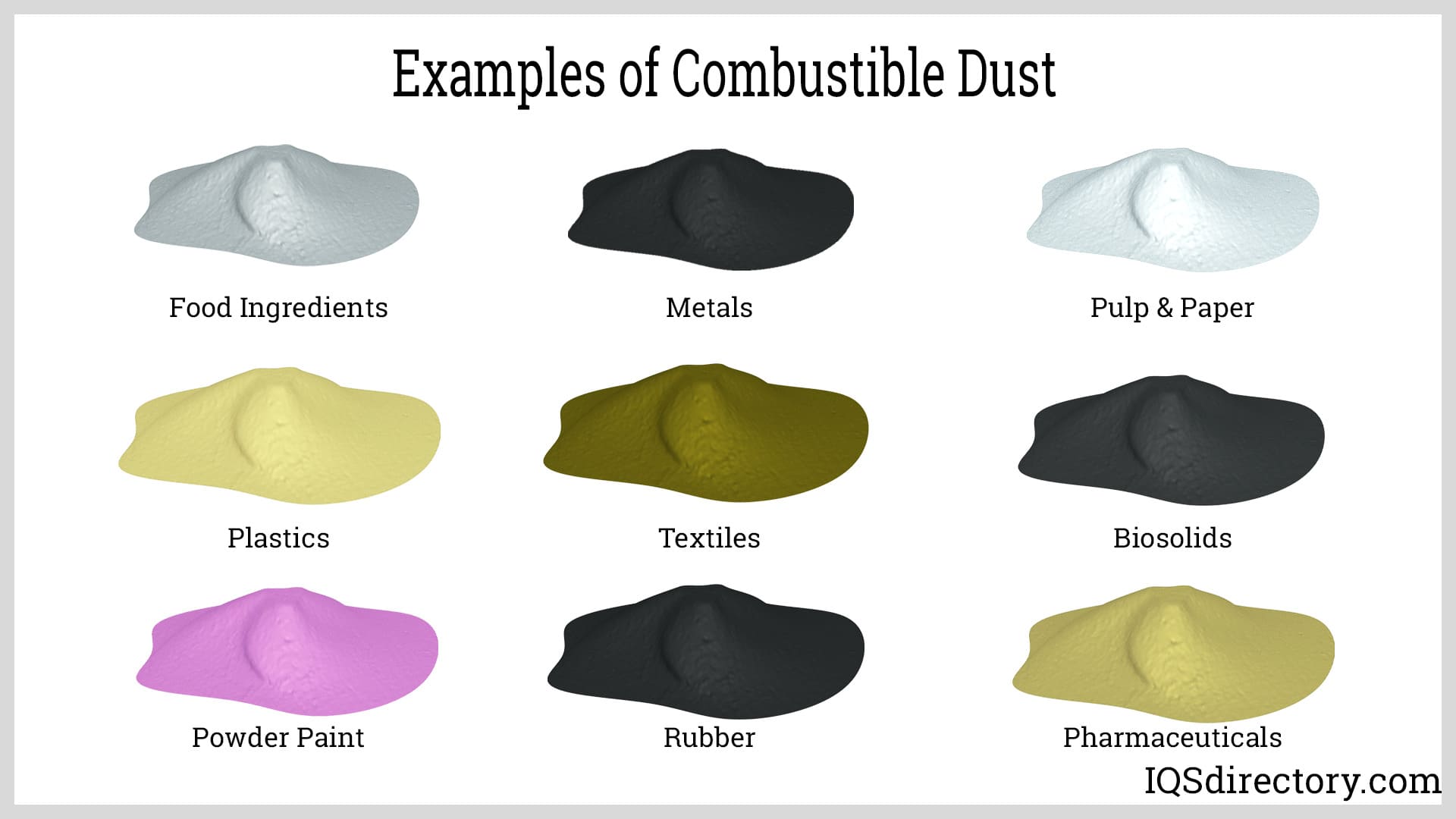

Portable dust collectors have a wide range of applications across various industries. Portable dust collectors are commonly used in woodworking and metalworking to capture sawdust, wood chips, metal shavings, and other debris. They are also used in construction to control dust and debris generated during concrete cutting or drilling. Moreover, they are suitable for general home use, particularly in workshops or garages, where dust and debris can accumulate quickly. They are also commonly used in the pharmaceutical industry to collect dust generated during the manufacturing process of medicines, which can be toxic to workers if inhaled. Moreover, portable dust collectors are widely used in the automotive industry to collect sanding dust, welding fumes, and exhaust fumes generated during the painting and welding process. They are also commonly used in the textile industry to capture fibers and dust generated during the weaving or cutting of fabrics. Portable dust collectors are also used in the chemical industry, meanwhile, to capture toxic or hazardous dust generated during the production of chemicals. In addition to these applications, portable dust collectors are also used in the mining industry to control dust generated during mining operations. They are used to collect coal dust, silica dust, and other particles that can be hazardous to workers' health. Finally, portable dust collectors are also used in the agriculture industry to control dust generated during farming activities such as harvesting, tilling, and processing of crops.

The Future and Portable Dust Collectors

As environmental concerns continue to grow, there is an increasing demand for sustainable and eco-friendly solutions. Portable dust collectors are energy-efficient and help control and capture dust and debris, making them an essential tool in maintaining a safe and healthy work environment. In the future, it is likely that regulations around air quality will become even more stringent, and the demand for effective dust collection systems will only increase. Portable dust collectors may become even more popular as a result, as they are versatile and suitable for a wide range of industries.

Another issue that may affect portable dust collectors in the future is the advancement of technology. As technology continues to evolve, new and more efficient dust collection systems may emerge. Portable dust collectors may need to adapt to new technologies to remain relevant and effective. For example, advancements in sensor technology and artificial intelligence could help improve the efficiency of dust collection systems, allowing them to capture even smaller particles more effectively.

In conclusion, the future of portable dust collectors looks bright, with the demand for sustainable and eco-friendly solutions on the rise. They are likely to continue to play a critical role in maintaining air quality and controlling dust and debris in various industries. However, to remain effective and relevant, portable dust collectors may need to adapt to new technologies and regulations, which could help improve their efficiency and effectiveness in capturing dust and other particles.

Choosing the Right Portable Dust Collector Supplier

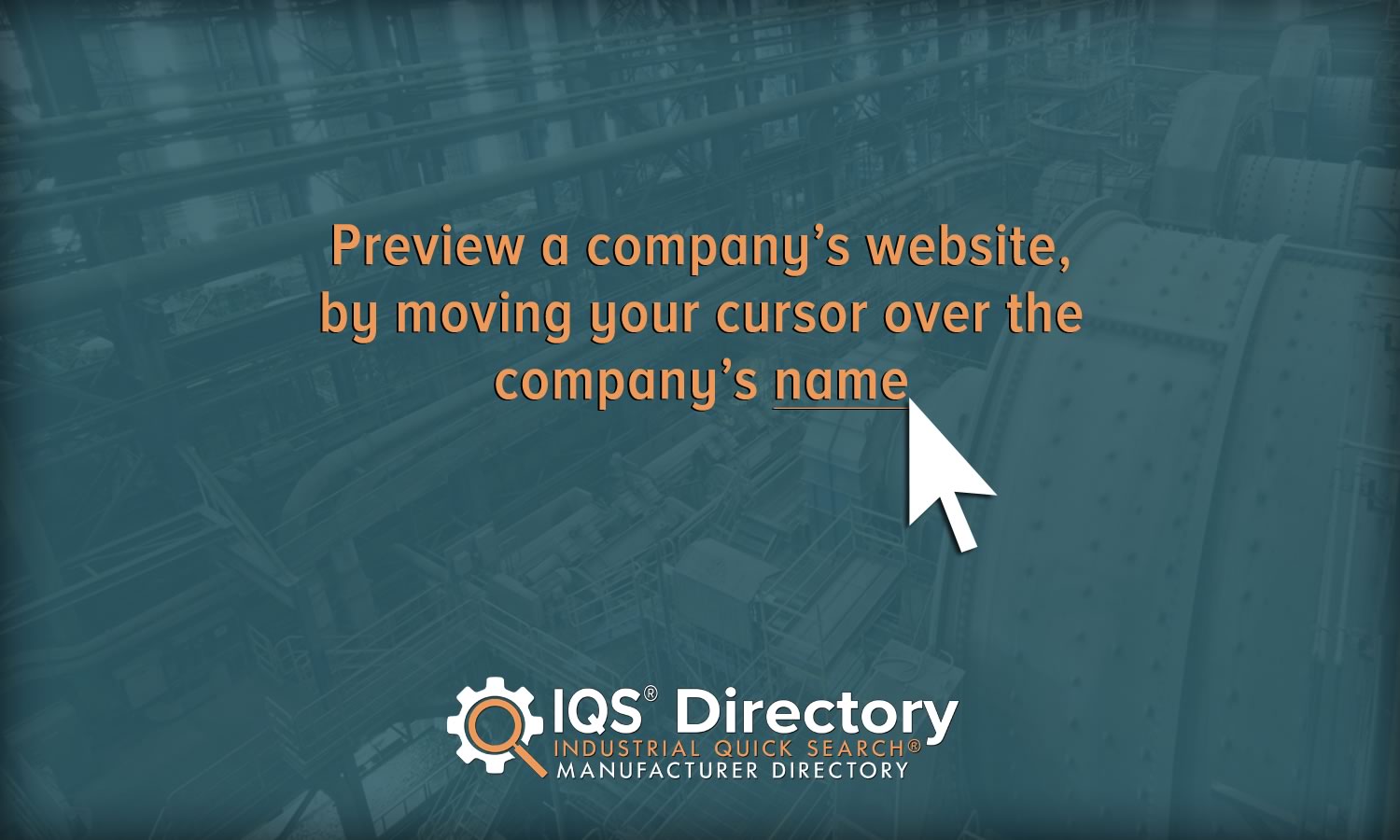

To ensure you have the most productive outcome when purchasing a portable dust collector from a portable dust collector supplier, it is important to compare several companies using our directory of portable dust collector suppliers. Each portable dust collector supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each portable dust collector business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple portable dust collector companies with the same form.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services