Jet dust collectors offer continuous operation and cleaning without interrupting the air flow because the short burst of air is so minor compared to the total volume of contaminated air in the device. As a result, jet dust collectors are typically not compartmentalized. Read More…

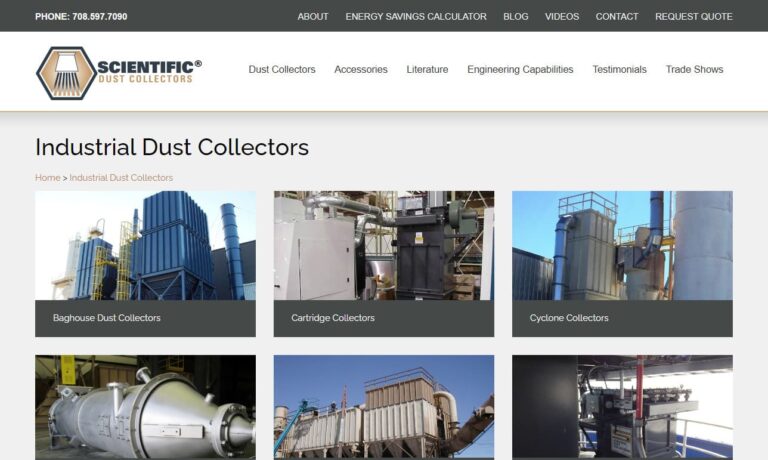

Since 1981, Scientific Dust Collectors has provided solutions for dust collecting, indoor air quality, separation equipment, and more. Our team of engineers has the capability to assist in the design of a dust collecting system and ducting that best fits your workplace. Design, engineering, and sales support are all done in one location at our Alsip, IL facility. Our goal is to give customers the ...

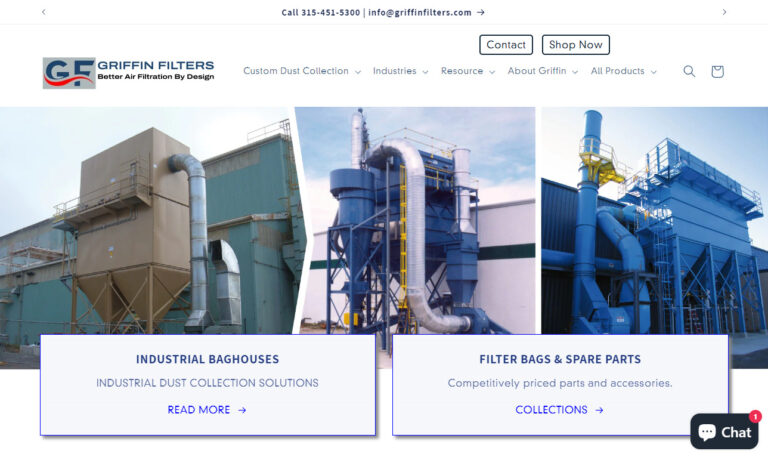

Griffin Filters is a trusted and dedicated leading manufacturer in the dust collector industry. We offer a wide selection of dust collectors with customization options available in order to serve various industries. Our experts are committed to manufacturing high-quality dust collectors that fit our customers' needs at competitive prices. Since its start in 1950, Griffin Filters has been setting...

Ever since our inception in 1989, Robovent has been a leader in the manufacturing and design of ventilation and filtration systems. We have experience coming up with solutions to protect our customers from a wide range of dust, including aluminum dust, cast iron grinding dust, fertilizer dust, and more. Industries we serve include automotive, military, construction, medical, and aerospace. For a...

Our world-class facilities set us apart from the competition. We work hard to make our customers happy with our air filters. We can provide what you need to keep your air clean in whatever industry you are in. Our goal is to exceed your expectations so you can focus on what you do best! Whether you need support in design, products, delivery, or support, we can supply it all!

Environmental Clean Air Company provides clean air solutions for a wide variety of indoor air quality problems. We offer a wide selection of dust collectors, mist collectors, welding booths, work containment booths, cyclones, electrostatic filters, air cleaning and filtration equipment to meet the demands of today's Industry.

At Coral USA Innovative Air Solutions , we are committed to delivering high-performance dust collection systems that enhance workplace safety, improve air quality, and ensure compliance with industry regulations. With extensive experience in air filtration and dust control, we design and manufacture advanced dust collectors that effectively capture and remove airborne contaminants, providing...

Our dust collecting systems are designed to eliminate respirable airborne contaminants from the work environment. We believe that eliminating airborne contamination in the workspace can lead to better employee performance.

More Jet Dust Collector Manufacturers

Jet dust collectors are one of the most widely used types of dust collecting systems because they require little maintenance, can clean high density dust and offer excellent filter efficiency. However, jet dust collectors take up more space than most other types of dust collectors, often requiring outdoor installation.

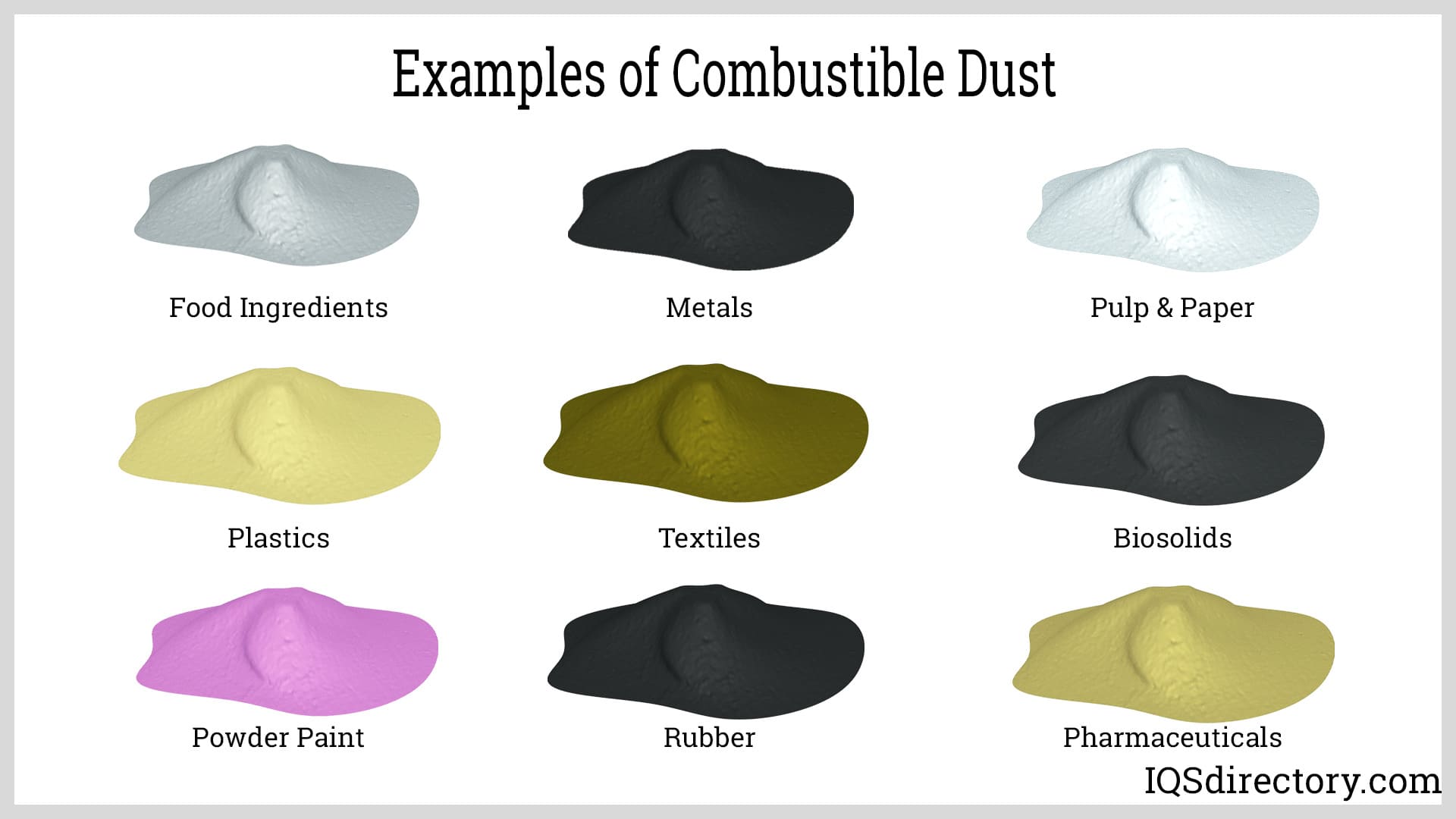

Industries that benefit from jet dust collectors include pharmaceutical, cement, iron and steel, petrochemical, agricultural, food processing, automotive and mining.

Ideal applications for jet dust collectors include product recovery, dust capturing, separating and filtering explosive media, metalworking chips, toxic media, central vacuum cleaning and pneumatic conveying.

A type of baghouse, jet dust collectors utilize fabric filters, or bags, to capture contaminated gas particulates and release clean air back into the workplace. In jet dust collection, the bags lined up in a row and are supported by a metal cage, which is fastened onto a cell plate, also called a tube sheet, at the top of the jet dust collector.

As contaminated air enters the jet dust collector, it flows from the outside to the inside of the bags. The metal cage ensures that the bags do not collapse from the additional weight. The bags are then cleaned by short bursts of compressed air that are controlled by a timer control board that utilizes a solenoid valve enclosure and a diaphragm valve on the outside of the filter housing.

The compressed air is then injected through a compressed air manifold that is mounted at the top of the jet dust collector over the row of bags. The compressed air is then accelerated due to venturi nozzles, nozzles that reduce fluid pressure resulting from fluid flowing through a constricted section of pipe, that are mounted over the top of each bag.

About 0.01 seconds, the burst of compressed air is so short that it acts as a rapid-motion air bubble, traveling through the entirety of the bag and causing the bag surfaces to flex. When the bag surfaces flex, the bag breaks the dust cake and the dislocated dirt falls into the storage hopper down below. The clean air then rises and exits out of an exhaust output at the top of the jet dust collector.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services