The pollutants produced in these environments, such as volatile organic compounds, hydrocarbon and solvent fumes, can have serious environmental and biological ramifications if not properly removed from the air and disposed of. Read More…

Since 1981, Scientific Dust Collectors has provided solutions for dust collecting, indoor air quality, separation equipment, and more. Our team of engineers has the capability to assist in the design of a dust collecting system and ducting that best fits your workplace. Design, engineering, and sales support are all done in one location at our Alsip, IL facility. Our goal is to give customers the ...

Griffin Filters is a trusted and dedicated leading manufacturer in the dust collector industry. We offer a wide selection of dust collectors with customization options available in order to serve various industries. Our experts are committed to manufacturing high-quality dust collectors that fit our customers' needs at competitive prices. Since its start in 1950, Griffin Filters has been setting...

Ever since our inception in 1989, Robovent has been a leader in the manufacturing and design of ventilation and filtration systems. We have experience coming up with solutions to protect our customers from a wide range of dust, including aluminum dust, cast iron grinding dust, fertilizer dust, and more. Industries we serve include automotive, military, construction, medical, and aerospace. For a...

Our world-class facilities set us apart from the competition. We work hard to make our customers happy with our air filters. We can provide what you need to keep your air clean in whatever industry you are in. Our goal is to exceed your expectations so you can focus on what you do best! Whether you need support in design, products, delivery, or support, we can supply it all!

Environmental Clean Air Company provides clean air solutions for a wide variety of indoor air quality problems. We offer a wide selection of dust collectors, mist collectors, welding booths, work containment booths, cyclones, electrostatic filters, air cleaning and filtration equipment to meet the demands of today's Industry.

At Coral USA Innovative Air Solutions , we are committed to delivering high-performance dust collection systems that enhance workplace safety, improve air quality, and ensure compliance with industry regulations. With extensive experience in air filtration and dust control, we design and manufacture advanced dust collectors that effectively capture and remove airborne contaminants, providing...

Our dust collecting systems are designed to eliminate respirable airborne contaminants from the work environment. We believe that eliminating airborne contamination in the workspace can lead to better employee performance.

More Industrial Dust Collector Manufacturers

Comprehensive Guide to Industrial Dust Collectors and Air Filtration Systems

Industrial dust collectors are essential components of modern manufacturing and processing facilities, playing a crucial role in maintaining optimal indoor air quality and ensuring the health and safety of workers. As environmental regulations and occupational safety standards become more stringent, businesses across various sectors are increasingly required to implement effective dust collection systems to mitigate air pollution, reduce workplace hazards, and comply with legal requirements.

Why Are Dust Collectors Required? (Understanding Regulatory Demands and Occupational Health)

Because of the potential hazards to worker health as well as other concerns related to air quality, regulatory and insurance agencies sometimes require that dust collectors be used to maintain healthy work environments. Agencies such as OSHA (Occupational Safety and Health Administration), EPA (Environmental Protection Agency), and NFPA (National Fire Protection Association) provide strict guidelines regarding permissible exposure limits (PELs) and air quality standards in workplaces where airborne particulates, fumes, or hazardous dust are generated.

Some regulations even require certain degrees of soundproofing be installed around these commonly loud machines to further protect workers. Implementing sound-dampening enclosures or noise-control solutions for dust collection equipment can help businesses meet these requirements and foster a safer, less disruptive work environment.

How Do Dust Collectors Benefit Industrial Facilities? (Productivity, Equipment Longevity, and Cost Savings)

The employees are not the only beneficiaries of dust collection as these devices improve productivity and equipment longevity. Even seemingly innocuous amounts of dust and debris can easily become trapped in motors and other equipment causing damage and, if allowed to accumulate, failure. Regular use of industrial dust extraction systems helps reduce unscheduled maintenance, prolongs machinery life cycles, and minimizes downtime due to equipment malfunctions.

By maintaining cleaner air quality and reducing dust accumulation, companies can experience:

- Enhanced operational efficiency and uninterrupted production

- Lower maintenance costs for plant equipment

- Improved product quality and consistency

- Reduced risk of fires or explosions from combustible dust

- Compliance with workplace safety and air quality regulations

Can Dust Collectors Support Sustainability and Resource Recovery?

In removing environmental dust or dust created as a byproduct of manufacturing, dust collectors also provide the possibility of recycling or reusing sometimes valuable dust. For example, metalworking applications often employ dust collectors to recover valuable titanium and other exotic metal dusts for a substantial cost savings. This process not only reduces waste disposal costs but also supports circular economy initiatives by allowing manufacturers to reclaim and repurpose materials that would otherwise be lost.

Are you interested in improving the sustainability of your facility? Discover dust collecting systems that facilitate resource recovery and environmental compliance.

Industries and Applications: Where Are Dust Collectors Used?

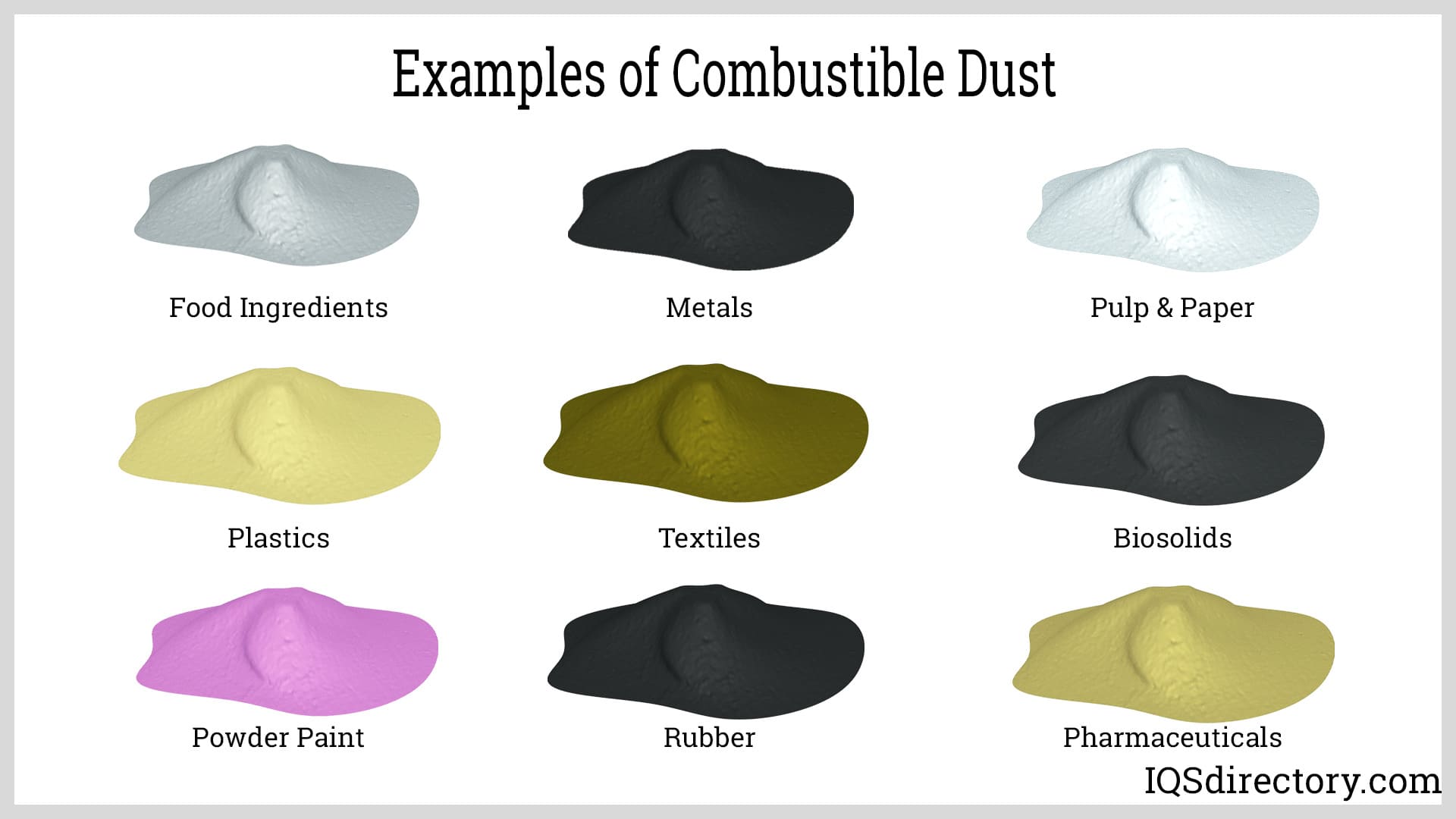

The many benefits of industrial dust collectors are reflected in their use in a broad array of industries including food processing, metallurgical processing, aerospace, electronics, woodworking, medical, pharmaceuticals, automotive manufacturing, plastics, and agriculture. Each sector has unique requirements for particulate removal, air purification, and regulatory compliance:

- Food Processing: Ensures sanitary conditions by removing flour dust, sugar dust, and other airborne contaminants.

- Metal Fabrication: Captures welding fumes, grinding dust, and metallic particulates for worker safety and resource recovery.

- Woodworking: Eliminates sawdust and fine wood particles, preventing respiratory issues and potential fire hazards.

- Pharmaceuticals: Controls hazardous chemical powders and helps meet Good Manufacturing Practice (GMP) standards for clean rooms.

- Electronics: Removes conductive dust and micro-particles that can damage sensitive circuit boards and components.

- Aerospace and Automotive: Protects sophisticated manufacturing environments from abrasive or combustible dusts.

- Agriculture: Safeguards processing plants by filtering grain dust, feed particulates, and other allergens.

Looking for dust collector solutions tailored to your industry? Explore custom dust collection systems by application.

How Dust Collectors Work: Core Components and Technologies

In general, dust collecting systems consist of a blower, dust filter, filter cleaning system, dust receptacle and dust removal system. Every industrial device will employ electrostatic precipitation, media filtration, inertia separation, air washing or any combination of these techniques to remove impurities from the workplace. Understanding the basic operation of these units can help buyers select the most efficient and cost-effective dust extraction technology for their needs.

Key components found in most industrial dust collectors include:

- Blower (Fan): Draws contaminated air into the system and maintains airflow through the filtration process.

- Dust Filter: Separates particulate matter from the airstream, using filter media such as fabric bags, cartridges, or HEPA filters.

- Filter Cleaning System: Removes accumulated dust from filters using mechanical shaking, reverse air pulses, or vibration to maintain optimal airflow.

- Dust Receptacle: Collects filtered dust for safe disposal or recycling.

- Dust Removal System: Transports collected dust from the system to designated storage or processing areas.

Common dust collection methods include:

- Electrostatic Precipitation: Uses electric charges to attract and collect dust particles on plates.

- Media Filtration: Employs physical barriers (filter bags, cartridges) to trap dust.

- Inertia Separation: Relies on changes in air velocity to separate heavier particulates from the airstream.

- Air Washing (Wet Scrubbing): Uses water or chemicals to capture and neutralize airborne contaminants.

Learn more about how dust collecting systems work and which technology best suits your facility's needs.

Types of Dust Collectors: Comparing Collection Technologies

The five most commonly used dust collectors are inertial separators, fabric filters, wet scrubbers, electrostatic precipitators and unit collectors, each offering different methods for specific needs. Selecting the right type depends on your facility's particulate profile, safety requirements, and operational goals.

- Inertial Separators (Cyclone Collectors): Utilize centrifugal force to remove larger dust particles and debris from the airstream. Ideal for pre-filtering or handling coarse particulates in bulk material handling and woodworking industries.

- Fabric Filters (Baghouse Collectors): Use woven or felted fabric bags to capture fine dust. Highly efficient for a range of dust types and widely used in cement, steel, and food processing plants.

- Wet Scrubbers: Remove hazardous and explosive dust by mixing air with water or chemical solutions. Essential for industries handling combustible or sticky particulates, such as aluminum and titanium processing.

- Electrostatic Precipitators: Charge and collect fine particles using high-voltage electrodes. Commonly found in power generation, chemical manufacturing, and pharmaceutical applications where ultra-fine filtration is required.

- Unit Collectors (Portable Dust Collectors): Compact systems designed for localized dust extraction at individual machines or workstations. Suitable for small-scale operations or retrofitting existing equipment.

Curious about which dust collector is right for your business? Compare dust collector types and request quotes from leading manufacturers.

Key Factors in Selecting an Industrial Dust Collector

There are many considerations when selecting an industrial dust collector. Understanding these factors will help you choose a system that meets both your operational and regulatory requirements while maximizing return on investment:

- Dust Type and Characteristics: Dust types can vary greatly to include hygroscopic, soluble in water, sticky, hazardous and explosive dust. For example, industries that produce fire hazardous dust such as aluminum and titanium often must use wet dust collectors as dry processes heighten the potential dangers of these flammable byproducts.

- Particle Size and Shape: Not only dust type, but particle shape must also be considered. Fine, fibrous, or abrasive particulates may require specialized filtration media or system designs.

- System Capacity and Airflow: Ensuring the dust collector can handle the volume of air and particulate load produced by your operations is vital for effective filtration and system longevity.

- Micron Size Filtration: Some facilities require ultra-fine filtration down to 0.3 microns or less, especially in pharmaceutical, electronics, or cleanroom environments.

- Construction Materials: Polypropylene construction is useful for corrosive dusts in low heat environments while stainless steel construction is used in most other applications. The choice of material impacts both durability and compatibility with collected particulates.

- Space Constraints: Available floor space, ceiling height, and ductwork access can influence whether you choose a central or a unit collector system.

- Maintenance Requirements: Consider ease of filter replacement, dust disposal, and automated cleaning systems to reduce labor and downtime.

- Energy Efficiency: Modern dust collectors can incorporate variable frequency drives (VFDs), energy recovery systems, and high-efficiency motors to reduce power consumption.

- Regulatory Compliance: Ensure the system meets OSHA, EPA, and NFPA standards for air quality, worker safety, and fire prevention.

Need help sizing or specifying a dust collection system? Contact dust collection experts for free consultations and site assessments.

What Are the Latest Trends and Innovations in Dust Collection?

The industrial dust collection market is constantly evolving, driven by advances in filtration media, automation, and smart controls. Recent innovations include:

- Self-cleaning filter technology that extends filter life and maintains airflow efficiency

- IoT-enabled monitoring systems for real-time performance tracking and predictive maintenance

- Modular, scalable designs that adapt to changing production needs

- HEPA and ULPA filtration for applications requiring medical-grade air purity

- Explosion-proof construction for industries with combustible dust risks

- Energy recovery solutions that reduce operational costs and environmental footprint

Want to stay ahead of regulatory changes or improve your facility’s air quality management? Learn about the latest dust collection technologies.

Frequently Asked Questions About Dust Collection Systems

- What is the difference between a dust collector and an air purifier?

While air purifiers are designed for general air cleaning in offices and residential spaces, industrial dust collectors are engineered to handle high volumes of airborne particulate matter, fumes, and hazardous dust generated by manufacturing processes. - How often should dust collector filters be replaced?

Replacement frequency depends on the type of dust, filter media, and system usage. Many modern systems use differential pressure sensors or automated cleaning cycles to optimize filter life. - What are the risks of neglecting dust collection in industrial settings?

Potential risks include regulatory fines, worker respiratory issues, equipment failure, fire or explosion hazards, and compromised product quality. - Can I retrofit an existing facility with a new dust collection system?

Yes, many manufacturers offer custom retrofits, modular upgrades, and portable units to accommodate existing plant layouts. - How do I calculate the required airflow (CFM) for my application?

Determining the correct cubic feet per minute (CFM) depends on the volume of dust generated, ductwork design, and process requirements. Consulting with a dust collection specialist is recommended for accurate sizing.

Benefits of Investing in High-Quality Dust Collection Systems

Investing in a reliable dust collector system offers significant returns for businesses seeking to protect workers, comply with regulations, and optimize production. Key benefits include:

- Healthier workplace with reduced employee absenteeism

- Lower risk of workplace accidents and regulatory violations

- Decreased equipment maintenance and replacement costs

- Sustainable operations through material recovery and waste reduction

- Improved corporate reputation and environmental stewardship

Ready to improve your facility’s air quality and operational efficiency? Request quotes for dust collection systems from leading suppliers.

Making the Right Choice: How to Evaluate Dust Collection System Providers

Choosing the right manufacturer or supplier is as important as selecting the right equipment. Consider the following when evaluating dust collection system providers:

- Industry experience and references from similar applications

- Customization capabilities for unique facility requirements

- After-sales support, maintenance, and spare parts availability

- Compliance with safety certifications and industry standards

- Warranty terms and performance guarantees

Looking for trusted partners? Explore our directory of dust collecting system manufacturers.

Next Steps: How to Get Started with Industrial Dust Collection

If you’re ready to enhance your facility’s air quality, protect your workforce, and ensure regulatory compliance, now is the time to act. Take these steps to begin your dust collection project:

- Identify the types and sources of dust in your facility

- Assess current air quality and regulatory requirements

- Define performance goals (filtration efficiency, energy savings, etc.)

- Consult with industry experts to evaluate system options

- Request site assessments and compare supplier proposals

- Plan for installation, commissioning, and ongoing maintenance

Have specific dust control challenges? Contact dust collection professionals for personalized recommendations and solutions.

Conclusion: Transforming Industrial Environments with Advanced Dust Collection

Effective dust collection is more than a regulatory requirement—it's a strategic investment in operational efficiency, safety, and sustainability. By understanding the different technologies, applications, and decision factors, you can select a dust collector system that not only meets compliance standards but also delivers long-term value for your business.

Whether you operate in food processing, metal fabrication, woodworking, pharmaceuticals, or other demanding sectors, the right dust collection system can make a measurable difference. Take the next step to improve your air quality, worker wellbeing, and bottom line.

Browse dust collecting system solutions today and build a safer, cleaner, and more productive industrial environment.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services