Downdraft tables have become a crucial component in various industrial and workshop settings. These tables are designed to capture harmful fumes, dust, and debris created during industrial processes, providing a safe and clean working environment. Read More…

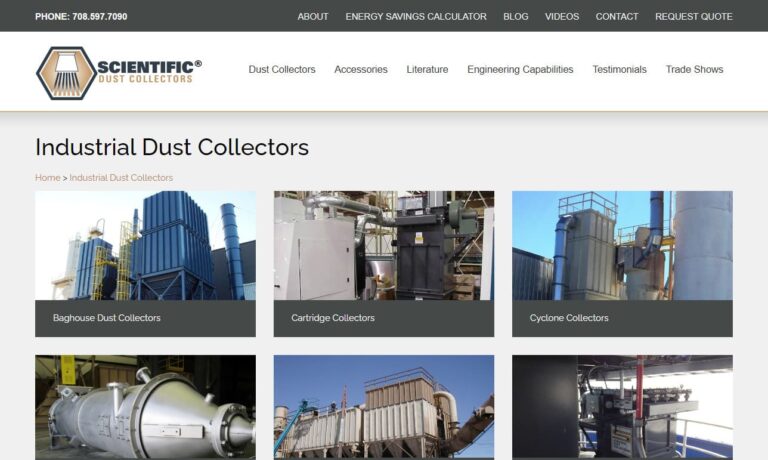

Since 1981, Scientific Dust Collectors has provided solutions for dust collecting, indoor air quality, separation equipment, and more. Our team of engineers has the capability to assist in the design of a dust collecting system and ducting that best fits your workplace. Design, engineering, and sales support are all done in one location at our Alsip, IL facility. Our goal is to give customers the ...

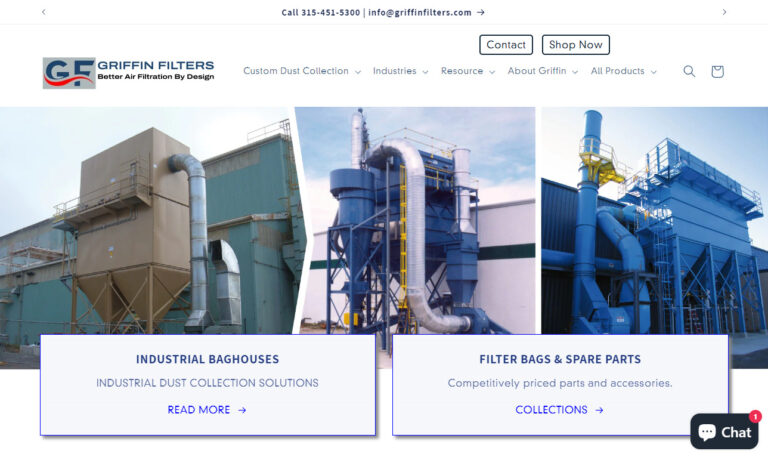

Griffin Filters is a trusted and dedicated leading manufacturer in the dust collector industry. We offer a wide selection of dust collectors with customization options available in order to serve various industries. Our experts are committed to manufacturing high-quality dust collectors that fit our customers' needs at competitive prices. Since its start in 1950, Griffin Filters has been setting...

Ever since our inception in 1989, Robovent has been a leader in the manufacturing and design of ventilation and filtration systems. We have experience coming up with solutions to protect our customers from a wide range of dust, including aluminum dust, cast iron grinding dust, fertilizer dust, and more. Industries we serve include automotive, military, construction, medical, and aerospace. For a...

Our world-class facilities set us apart from the competition. We work hard to make our customers happy with our air filters. We can provide what you need to keep your air clean in whatever industry you are in. Our goal is to exceed your expectations so you can focus on what you do best! Whether you need support in design, products, delivery, or support, we can supply it all!

Environmental Clean Air Company provides clean air solutions for a wide variety of indoor air quality problems. We offer a wide selection of dust collectors, mist collectors, welding booths, work containment booths, cyclones, electrostatic filters, air cleaning and filtration equipment to meet the demands of today's Industry.

At Coral USA Innovative Air Solutions , we are committed to delivering high-performance dust collection systems that enhance workplace safety, improve air quality, and ensure compliance with industry regulations. With extensive experience in air filtration and dust control, we design and manufacture advanced dust collectors that effectively capture and remove airborne contaminants, providing...

Our dust collecting systems are designed to eliminate respirable airborne contaminants from the work environment. We believe that eliminating airborne contamination in the workspace can lead to better employee performance.

More Downdraft Table Manufacturers

Components of Downdraft Tables

To understand how these tables work, it is essential to examine their components, which include the table, fan, filters, and ductwork. The table is typically made of a perforated surface that allows air to be drawn downwards into the table's interior. The fan creates negative pressure, pulling the contaminants down through the table and into the filters, where they are removed before clean air is expelled through the ductwork.

Variations of Downdraft Tables

There are several variations of downdraft tables available, each designed to meet the specific needs of different industries and processes. One variation is the portable downdraft table, which is designed to be easily moved from one workspace to another, making it ideal for applications that require flexibility and mobility. Another variation is the custom downdraft table, which can be customized to fit the specific needs of each workspace, including size, shape, and power requirements. An additional variation is the downdraft booth, which provides a larger workspace for industrial applications that require more space.

Considerations Regarding Downdraft Tables

While downdraft tables provide many benefits, they also have potential effects that should be considered. One of the most significant considerations is the noise created by the fan, which can be disruptive to workers and may require additional hearing protection. Additionally, while downdraft tables are designed to improve air quality, proper ventilation and maintenance are essential to ensure that the air quality is not negatively impacted. Furthermore, their filters require frequent replacement or cleaning, which can be time-consuming and expensive. Finally, the initial cost of purchasing and installing a downdraft table can be significant.

Benefits of Downdraft Tables

On the other hand, downdraft tables provide many benefits to various industries. One of the most significant benefits is improved air quality. By capturing harmful fumes, dust, and debris, downdraft tables create a safer and cleaner working environment, reducing the risk of respiratory issues and other health concerns for workers. Also, downdraft tables can increase worker safety by preventing accidents caused by debris, reducing the risk of slips, trips, and falls, and providing a clear workspace for workers. Additionally, downdraft tables can increase efficiency by reducing cleanup time and preventing equipment damage caused by debris. Another benefit of downdraft tables is their flexibility. Downdraft tables can be customized to fit the specific needs of each workspace, including size, shape, and power requirements. This allows for greater efficiency and effectiveness in capturing contaminants and reducing the risk of accidents. Finally, downdraft tables can also be used as a training tool, allowing workers to learn about potential hazards in their work environment and how to prevent them. By using downdraft tables, workers can better understand the importance of maintaining a clean and safe workspace, reducing the risk of accidents and injuries.

Applications of Downdraft Tables

Downdraft tables have a wide range of applications across various industries. In metalworking, for instance, downdraft tables can be used to capture fumes and debris generated during welding, grinding, and sanding processes, thereby providing a clean and safe work environment for workers. In woodworking, meanwhile, downdraft tables can be used to capture sawdust, reducing the risk of respiratory issues and increasing efficiency by preventing sawdust from interfering with equipment. Additionally, the automotive industry uses downdraft tables for sanding, painting, and other processes in order to reduce the risk of contaminants and improve air quality.

Another application of downdraft tables is in the food industry. They can be used to capture dust and debris generated during food preparation and processing, reducing the risk of contamination and improving cleanliness in the work environment. Furthermore, the pharmaceutical industry uses downdraft tables to capture dust and other contaminants generated during the production of medications, thereby reducing the risk of contamination and improving air quality in the workspace. Additionally, downdraft tables are used in educational settings to provide a safe and clean workspace for students in technical and vocational training programs. Finally, downdraft tables are used in art studios to capture dust and debris generated during the creation of sculptures and other art forms in order to improve air quality and reduce the risk of respiratory issues for artists.

Choosing the Correct Downdraft Table Supplier

To ensure you have the most favorable outcome when purchasing a downdraft table from a downdraft table supplier, it is important to compare several companies using our directory of downdraft table suppliers. Each downdraft table supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each downdraft table business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple downdraft table companies with the same form.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services