For this reason they are often used as pre-filtering modules for bag houses and cartridge collectors. Cyclone dust collectors serve industries such as ore processing, pharmaceutical, cement fabrication, metal fabrication, mining, chemical processing, recycling and agricultural industries. Read More…

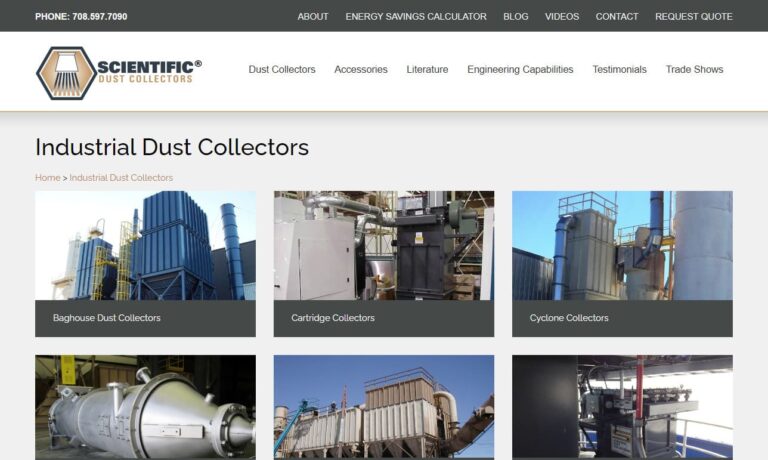

Since 1981, Scientific Dust Collectors has provided solutions for dust collecting, indoor air quality, separation equipment, and more. Our team of engineers has the capability to assist in the design of a dust collecting system and ducting that best fits your workplace. Design, engineering, and sales support are all done in one location at our Alsip, IL facility. Our goal is to give customers the ...

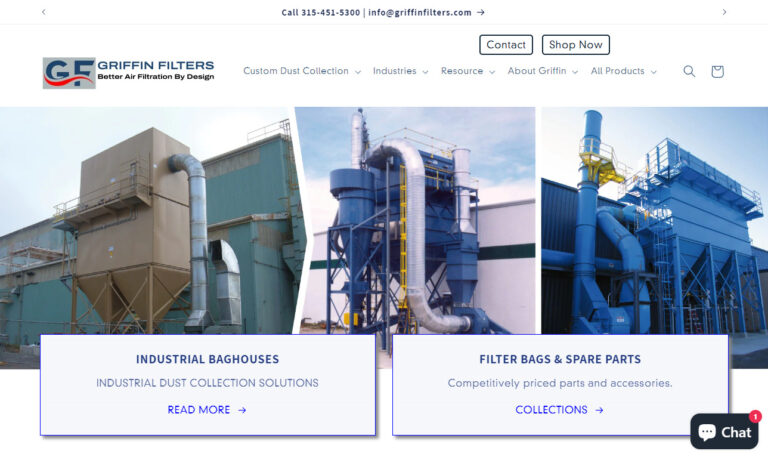

Griffin Filters is a trusted and dedicated leading manufacturer in the dust collector industry. We offer a wide selection of dust collectors with customization options available in order to serve various industries. Our experts are committed to manufacturing high-quality dust collectors that fit our customers' needs at competitive prices. Since its start in 1950, Griffin Filters has been setting...

Ever since our inception in 1989, Robovent has been a leader in the manufacturing and design of ventilation and filtration systems. We have experience coming up with solutions to protect our customers from a wide range of dust, including aluminum dust, cast iron grinding dust, fertilizer dust, and more. Industries we serve include automotive, military, construction, medical, and aerospace. For a...

Our world-class facilities set us apart from the competition. We work hard to make our customers happy with our air filters. We can provide what you need to keep your air clean in whatever industry you are in. Our goal is to exceed your expectations so you can focus on what you do best! Whether you need support in design, products, delivery, or support, we can supply it all!

Environmental Clean Air Company provides clean air solutions for a wide variety of indoor air quality problems. We offer a wide selection of dust collectors, mist collectors, welding booths, work containment booths, cyclones, electrostatic filters, air cleaning and filtration equipment to meet the demands of today's Industry.

At Coral USA Innovative Air Solutions , we are committed to delivering high-performance dust collection systems that enhance workplace safety, improve air quality, and ensure compliance with industry regulations. With extensive experience in air filtration and dust control, we design and manufacture advanced dust collectors that effectively capture and remove airborne contaminants, providing...

Our dust collecting systems are designed to eliminate respirable airborne contaminants from the work environment. We believe that eliminating airborne contamination in the workspace can lead to better employee performance.

More Cyclone Dust Collector Manufacturers

Cyclone Dust Collectors: Industrial Air Filtration Solutions for High-Dust Environments

Cyclone dust collectors are essential industrial air filtration devices designed to efficiently capture and separate particulate matter from process air. These high-performance dust separation systems are widely utilized in industries facing elevated dust concentrations, including paper converting, product recovery, scrap metal recycling, chemical processing, steel sintering, cement production, woodworking, metal fabrication, and general gas cleaning.

What Is a Cyclone Dust Collector? How Does It Work?

A cyclone dust collector, also known as a cyclone separator or cyclone air separator, is a robust, cylindrically-shaped inertial separator engineered to remove dust, debris, and non-combustible particulates from an air stream without the use of filter media. The core principle involves harnessing centrifugal force within a conical or hopper-shaped chamber to separate contaminants from the process airflow.

During operation, contaminated air or process gases are introduced tangentially into the upper portion of the cyclone. The involute (spiral) entry causes the gas stream to spin rapidly, creating a vortex. Heavier dust particles and solid contaminants are flung outward by centrifugal force, impacting the cyclone wall and migrating downward into a collection hopper. Meanwhile, cleaned air spirals upward through a central outlet tube and is exhausted, often to a further filtration stage or directly outdoors.

Key components of a cyclone dust collector typically include:

- Cylindrical body and conical hopper: The main separation chamber, designed for optimal airflow patterns.

- Tangential air inlet: Where dirty air enters the cyclone separator at high velocity.

- Vortex finder or outlet tube: Central tube that allows the cleaned air to exit the cyclone.

- Dust collection chamber: The lower section or bin where separated particulates accumulate for disposal or recycling.

- Blower or exhaust fan: Drives airflow, often integrated with the dust collector system.

The inner vortex, or helix, is often powered by an electric motor mounted on the top or bottom of the cyclone. Advanced systems may incorporate variable speed drives and automated controls to optimize performance for specific applications and dust loads.

Types of Cyclone Dust Collectors: Single and Multi-Cyclone Designs

Industrial cyclone dust collectors are available in a range of configurations to suit different process requirements and dust characteristics. The two primary categories are:

- Single-Cyclone Dust Collectors: The classic design, featuring a single large cyclone chamber. Best suited for processes with larger particle sizes and moderate air volumes. Common in woodworking shops, sawmills, and primary process filtration.

- Multi-Cyclone Dust Collectors: Comprise numerous small-diameter cyclones arranged in parallel, each equipped with vane spinners to enhance separation efficiency. Multi-cyclone collectors offer higher removal rates for fine particulates and are ideal for large-scale industrial facilities, such as cement plants, chemical refineries, and steel mills.

Both single-cyclone and multi-cyclone dust collector designs are widely used across diverse industries. Multi-cyclone systems, in particular, are preferred for their superior efficiency in capturing fine dust and their ability to handle large volumes of air with minimal pressure drop.

Common Industrial Applications for Cyclone Dust Collectors

Cyclone dust collectors are integral to maintaining safe, healthy, and compliant work environments across numerous sectors. Typical applications include:

- Paper Converting and Printing: Capturing paper dust and trimming waste generated during high-speed converting lines.

- Product Recovery: Recovering valuable process materials, such as powdered chemicals, food ingredients, or pharmaceutical excipients, from process exhaust streams.

- Scrap Metal Recycling: Removing metallic dust, shavings, and abrasive grit produced in shredding and grinding operations.

- Chemical Processing: Controlling dust emissions in the production of detergents, fertilizers, pigments, and resins.

- Steel Sintering and Foundries: Managing heavy dust and particulate emissions during ore processing and metal casting.

- Cement, Lime, and Aggregate Plants: Pre-cleaning air before baghouse filtration and reducing dust load on downstream filters.

- Woodworking and Furniture Production: Extracting sawdust, wood chips, and fine particulates from cutting, sanding, and routing processes.

- Pharmaceutical Manufacturing: Collecting dust from tablet presses, granulators, and other processing equipment to maintain product purity and comply with cGMP standards.

- General Industrial Air Pollution Control: Serving as a primary or secondary stage in comprehensive dust collection systems.

Facilities often incorporate cyclone dust collectors into large-scale dust collecting systems, featuring extensive overhead ductwork and strategically positioned capture arms (suction hoods) above dust-generation points. In many of these installations, the cyclone dust collector is located outdoors, connected to the facility's interior via robust ducting to minimize indoor noise and maximize usable floor space.

Benefits of Cyclone Dust Collectors in Industrial Dust Control

Why do so many industrial buyers choose cyclone dust collectors as a core component of their air filtration strategy? Cyclone separators offer several distinct advantages:

- High Efficiency Particle Separation: Cyclone collectors effectively remove up to 99% of coarse and medium-sized particles from process air, reducing dust emissions and protecting downstream equipment.

- Low Maintenance and Operating Costs: With no filter media to replace or clean, cyclone dust collectors require less frequent maintenance and are less prone to pressure drop or clogging.

- Durable, Heavy-Duty Construction: Cyclones are typically fabricated from steel or stainless steel for long service life, even in abrasive or corrosive environments.

- Pre-Filtration for HEPA or Baghouse Systems: By removing larger particles, cyclones extend the life and efficiency of secondary filters such as baghouses, cartridge collectors, or HEPA filters.

- Versatility and Scalability: Modular cyclone designs can be engineered for small lab-scale applications or massive industrial installations handling hundreds of thousands of CFM (Cubic Feet per Minute).

- Energy Efficiency: Properly designed cyclone systems minimize pressure drop, reducing fan energy consumption compared to high-resistance filter systems.

- Compliance with Environmental Regulations: Cyclone collectors help facilities meet OSHA, EPA, and local air quality standards by capturing fugitive dust emissions at the source.

Curious about how a cyclone dust collector can improve your facility’s air quality and worker safety? Contact a dust collection systems expert for a free consultation, or compare industrial dust collector types to find the right solution for your application.

Key Considerations When Selecting a Cyclone Dust Collector

Choosing the right cyclone dust collector involves careful evaluation of your process requirements, dust characteristics, and facility layout. Before investing in a cyclone separator, consider the following factors:

- Airflow Volume and Velocity: Sizing the cyclone for your required CFM ensures optimal separation efficiency and avoids system bottlenecks.

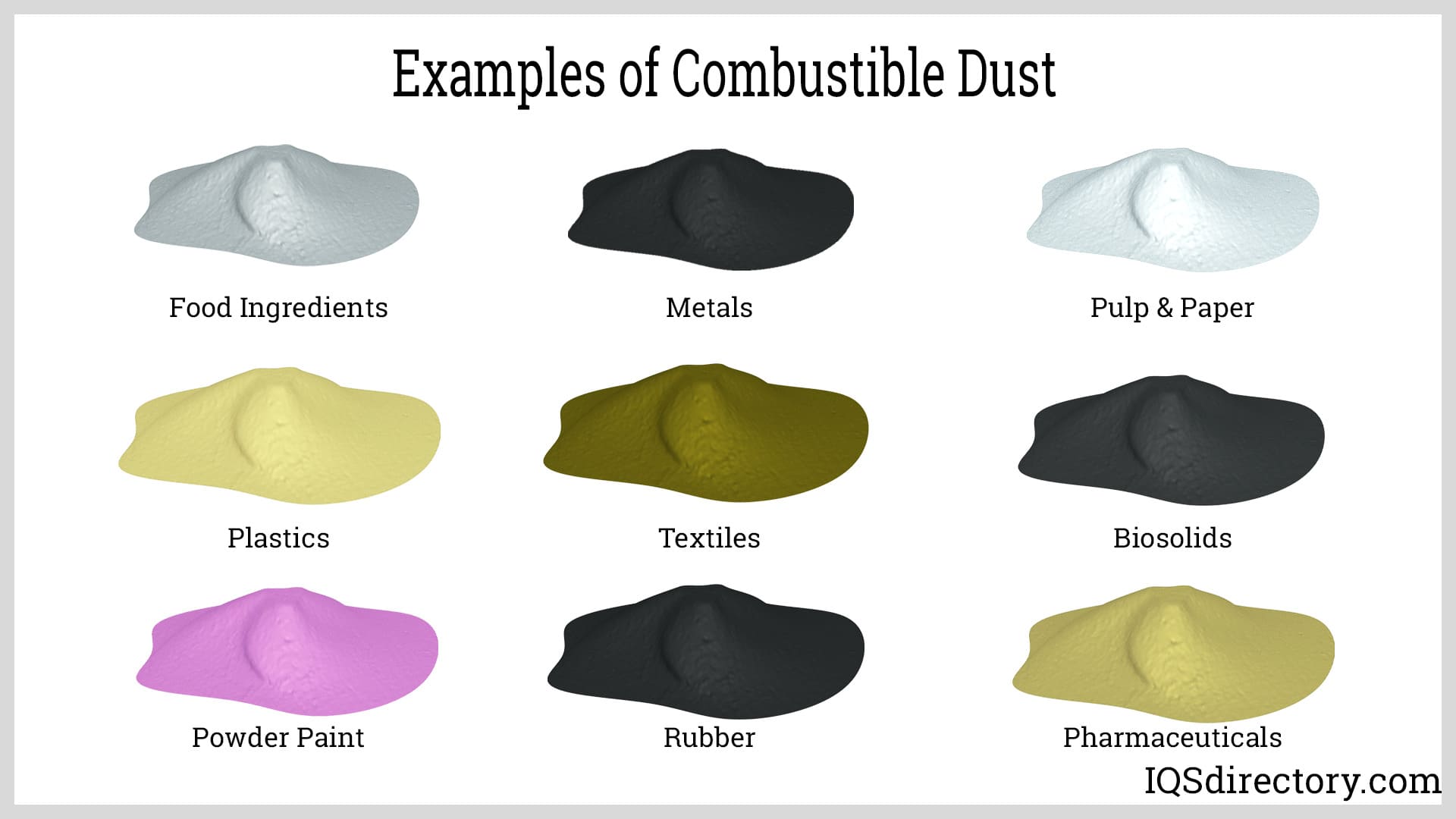

- Particle Size Distribution: Cyclones are most effective for particles greater than 10 microns; finer particles may require secondary filtration stages.

- Dust Loading and Material Properties: Abrasive, sticky, or fibrous dusts can impact cyclone performance and durability—material selection and wear protection may be needed.

- System Integration: Will the cyclone operate as a standalone pre-filter, or as part of a multi-stage dust collection system with baghouses, filters, or scrubbers?

- Space Constraints and Installation Location: Consider available floor space, headroom, and whether the collector should be installed indoors or outdoors.

- Discharge Method: Options include manual bins, rotary airlocks, screw conveyors, or pneumatic transfer for automated dust disposal or recycling.

- Maintenance Access and Safety: Ensure your design allows for safe, easy access for inspection, cleaning, and repairs.

Looking for a step-by-step guide to sizing and specifying an industrial cyclone dust collector? Download our cyclone selection checklist or speak with a systems engineer for custom recommendations.

Comparing Cyclone Dust Collectors to Other Dust Collection Technologies

How do cyclone dust collectors stack up against other industrial dust collection solutions? Here’s a quick overview:

- Baghouse Dust Collectors: Use fabric filter bags to capture fine and ultra-fine dust. Best for critical air quality applications, but require regular filter changes and maintenance.

- Cartridge Dust Collectors: Employ pleated filter cartridges for high-efficiency filtration of fine particulates. Compact footprint but best for lighter dust loads.

- Wet Scrubbers: Utilize liquid spray to remove particulates and gases; ideal for sticky, combustible, or toxic dusts that clog dry filters.

- Electrostatic Precipitators: Use electric charges to trap fine particles; highly efficient but costly and complex.

- Cyclone Dust Collectors: Robust, low-maintenance, and effective for high-dust, non-combustible applications. Often used as pre-filters to reduce load on fine filtration equipment.

Each technology has strengths and limitations—cyclones excel in heavy dust loading, coarse particulate removal, and low-maintenance operation. For best results, many facilities combine cyclones with secondary filter systems, creating a multi-stage dust collection process tailored to their unique needs.

Frequently Asked Questions About Cyclone Dust Collectors

- What particle size can a cyclone dust collector remove?

Cyclone separators are most effective for particles 10 microns and larger. For finer dust, consider using a cyclone as a pre-filter, followed by baghouse or cartridge filtration. - How much maintenance does a cyclone dust collector require?

Cyclones have no filter media to replace and minimal moving parts, resulting in low maintenance. Periodic inspection and cleaning of the cyclone chamber and discharge bin is recommended. - Can cyclone collectors handle combustible dust?

Cyclones are suitable for non-combustible dust. For combustible or explosive dust, ensure compliance with NFPA standards and consider explosion protection measures. - Are cyclone dust collectors suitable for indoor installation?

While possible, most large cyclones are installed outdoors due to their size and noise; compact or mobile cyclone units are available for laboratory and small workshop use. - How do I size a cyclone dust collector for my application?

Sizing depends on process air volume, dust loading, particle size, and specific application needs. Consult with a dust collection systems provider for detailed engineering support.

Enhance Your Facility’s Air Quality: Next Steps

Ready to improve your industrial air filtration and dust control strategy? Cyclone dust collectors are a cost-effective, proven solution for managing airborne particulates, protecting worker health, and ensuring regulatory compliance in high-dust environments. Whether you’re upgrading an existing facility or designing a new dust collection system, partnering with an experienced manufacturer or systems integrator is crucial for optimal performance.

To explore customized cyclone dust collector options, request a quote or schedule a consultation with a dust collection specialist. They can help you assess your unique requirements, recommend the ideal cyclone system configuration, and ensure seamless integration into your facility’s workflow.

For further research, browse our in-depth resources on:

Still have questions? Ask us: What is the best cyclone dust collector for my industry? Or, compare cyclone dust collector prices and features to make an informed buying decision.

Conclusion: Why Cyclone Dust Collectors Remain a Top Choice for Industry

Cyclone dust collectors continue to be a mainstay of industrial air pollution control due to their robust performance, low maintenance requirements, and versatility in handling a wide range of dust types and process conditions. When properly specified and integrated, cyclone separators can dramatically reduce airborne particulate levels, safeguard worker health, and prolong the life of critical equipment. Whether you need a heavy-duty multi-cyclone for a cement plant or a compact cyclone separator for a laboratory, these systems deliver reliable, cost-effective dust management for virtually any industrial setting.

Discover how cyclone dust collectors can transform your facility’s air quality and operational efficiency. Reach out to a trusted supplier today, or use our online tools to compare models and request customized recommendations.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services