More Dust Collecting System Manufacturers

Dust collecting systems—also known as industrial dust collection systems or dust extraction systems—are engineered to significantly improve indoor air quality within industrial, manufacturing, and commercial settings. These specialized air filtration machines consist of several crucial components working together to capture, convey, and filter out harmful airborne dust particles. By minimizing atmospheric contamination, dust collection systems ensure a safer, healthier, and more productive work environment. They are commonly deployed in locations such as manufacturing facilities, woodworking shops, metal fabrication plants, food processing lines, and chemical processing plants, where airborne particulates pose operational, regulatory, and health challenges.

Why Use Dust Collecting Systems?

Although it is usually vague, the term dust can be defined as any minuscule, solid, and airborne particle produced by some process of physical disintegration or mechanical processing. Most fabrication and manufacturing industries depend on processes—such as cutting, grinding, sanding, milling, or blending—that inevitably release dust particles into the air. These particles pose a direct threat to the well-being of industrial equipment and the workers who manage them.

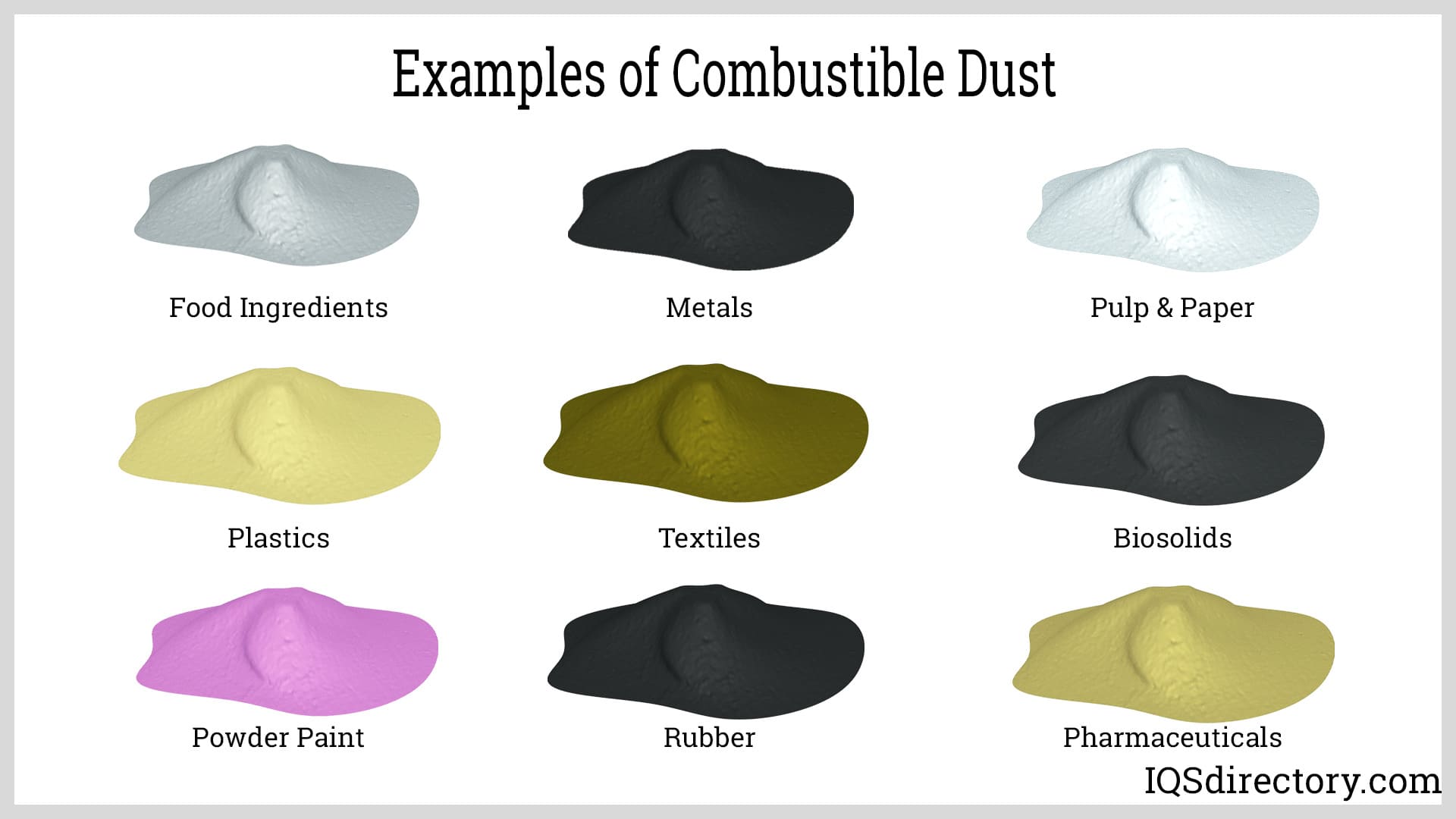

The health risks associated with dust contamination are substantial: respiratory health issues such as bronchitis, severe asthma, chronic obstructive pulmonary disease (COPD), silicosis, and even cancer can result from long-term exposure to industrial dust. Some of these and similar issues are caused by fine chemicals, heavy metals, or fungi embedded within industrial dust. In addition, dust contamination increases the risk of workplace fire or catastrophic explosions, especially when combustible dusts—such as wood dust, flour, or metal shavings—accumulate in sufficient quantities.

Industrial dust collecting systems are purpose-built to minimize these threats by efficiently capturing harmful dust at the source, transporting it away from critical workspaces, and filtering harmful particles before they can recirculate. Some disadvantages of these systems include the physical space they require and their complex, often permanent installation, which can make reconfiguration difficult. However, most industrial businesses find dust collection systems indispensable—not only to comply with governmental standards for regulating air quality and emissions (such as OSHA, NFPA, and EPA regulations), but also to safeguard employee health, prevent equipment malfunctions, and maintain product quality.

While the initial cost and installation effort for dust collection systems may seem high, these systems generally provide substantial long-term value—enabling more effective particle reduction, prolonging the lifespan of machinery, improving overall working conditions, and reducing liability risks for employers. If you are asking, “How do I choose the right dust collector for my facility?” or “What is the ROI of investing in a dust collection system?”—explore further below for details on types, applications, and selection criteria.

How Dust Collection Systems Work

Industrial dust collection systems for cleaning air generally follow three key steps: capturing contaminated air at or near the source, transporting it to a central collection unit via ductwork and pressure differentials, and filtering out harmful substances before expelling clean, filtered air back into the environment or exhausting it outdoors.

Despite variations in design, most dust collection systems share several core components:

- Capture Devices: Suction hoods, also known as exhaust hoods, capture arms, or extraction points, are positioned over or attached to dust-producing equipment—such as woodworking machines, metal grinders, or mixing tanks—to capture dust at the source before it can disperse.

- Ductwork: Ducts act as passageways, transporting the contaminated air from multiple capture points to the central suction unit. Proper duct sizing and layout are critical for maintaining optimal airflow and minimizing static pressure loss.

- Fans/Blowers: A powerful fan or blower creates the necessary airflow to draw dust-laden air through the ducts and into the collection system.

- Dust Collectors/Filters: The system’s “heart” is the filtration unit, which may include fabric filters, cartridge filters, cyclones, or wet scrubbers. These components are responsible for removing harmful particles from the air stream.

- Clean Air Outlet: After filtration, purified air is either re-circulated back into the workspace (important for energy efficiency in climate-controlled environments) or exhausted outdoors in compliance with environmental regulations.

In addition, modern dust collection systems often feature automated cleaning mechanisms, monitoring sensors, and smart controls for optimized performance and compliance. Systems can be customized to address specific challenges, such as the recovery of valuable process dust (e.g., precious metal shavings), odor control, or the capture of hazardous dust (e.g., silica, asbestos).

Are you curious about how to improve air quality in your facility or how to reduce dust-related maintenance costs? Discover the latest advancements in industrial dust collection technology below.

Types of Dust Collection Systems

Dust collection systems are fundamentally defined by their filtration components, which form the core of their operation. The choice of filter—fabric, cartridge, HEPA, electrostatic, or wet—depends on the application, particle type, and regulatory requirements. Filters can be fabricated from synthetic cellulose, polyester-silicon complexes, fiberglass, PTFE membrane, or woven cloth, offering a range of efficiencies and durability for different industries.

These systems often use multiple types of collectors to address varying dust loads and particle sizes. Below is an overview of some common and notable types, along with their primary applications and advantages:

- Baghouse Dust Collectors: The most prevalent and efficient industrial dust collectors. Baghouses use powerful fans to create a vacuum that pulls contaminated air through fabric filter bags. Dust particles are trapped on the bag surface while clean air exits the unit. To maintain efficiency, baghouse filters are periodically cleaned using one of several methods:

- Shaker Collectors: Mechanically shake the bags at intervals to dislodge accumulated dust for collection and disposal.

- Reverse Air Collectors: Temporarily reverse the airflow to reduce dust buildup and clean the filter bags.

- Jet Collectors (Pulse Jet): Use high-pressure air jets to clean the bags automatically and efficiently.

Baghouse systems are especially effective for large-scale manufacturing, foundries, food processing, and chemical plants where fine particulate removal and continuous operation are required.

- Cyclone Dust Collectors: Also known as cyclone separators, these inertial separators use centrifugal force to separate heavy dust particles from the air stream within a cone- or hopper-shaped chamber. As contaminated air enters tangentially, a rotating vortex is created, forcing particles against the chamber wall where they lose momentum and settle out. Variants include skimmer cyclones, reverse-flow cyclones, axial flow cyclones, and secondary airflow dust collectors. Cyclones are ideal as pre-filters for bulk material handling, woodworking, grain processing, and as a first stage in multi-stage dust collection systems.

- Dust Extraction Systems: These comprehensive systems are crucial for production facilities, workshops, factories, and industrial complexes. They efficiently filter particulate contaminants from the air, helping to maintain a clean and safe environment. Industries such as mining, asphalt production, chemical processing, welding, pharmaceuticals, food processing, and plastics manufacturing benefit from these systems. They also act as fire suppression systems by collecting flammable and explosive dust, reducing odors, and ensuring compliance with safety and environmental regulations. Proper dust extraction directly enhances product quality, worker morale, and overall process efficiency.

- Baffle Chamber Dust Collectors: Operating on principles similar to cyclones, baffle chambers use stationary baffle plates to rapidly redirect contaminated air, causing large dust particles to lose momentum and settle in collection zones. These are suitable for applications where larger particulate matter predominates, such as sawmills, grain handling, and primary crushing operations.

- Wet Scrubbers: These systems clean air by forcing it through a scrubbing liquid—typically water or a chemical solution. The effectiveness of the scrubber is determined by the thoroughness of air/liquid contact. Water droplets capture dust particles, which are then separated and collected. After passing through the scrubber, the air is dehumidified by mist eliminators. Wet scrubbers are ideal for applications requiring the removal of both dust and gaseous pollutants, such as chemical manufacturing, pharmaceuticals, food processing, and metal finishing. Types include:

- Wetted Surface Scrubbers: E.g., baffle spray scrubbers, cyclonic spray scrubbers, fibrous bed scrubbers.

- Distributed Liquid Scrubbers: E.g., spray tower scrubbers, plate tower scrubbers, self-induced spray scrubbers.

- Electrostatic Precipitators (ESPs): These advanced filtration systems use charged ions to attract and capture dust particles, which are then deposited on collection electrodes. ESPs can be single-stage or double-stage, depending on whether charging and collection occur in the same area. They are popular in power plants, cement kilns, steel mills, and other facilities where ultra-fine particulate control is necessary. Removal methods include mechanical rapping, liquid film, or liquid spray.

- Central and Portable Dust Collection Systems: Central systems are permanently installed and connect to dust sources via a network of ducts—ideal for large industrial settings requiring high-capacity, continuous operation. Portable collectors offer localized dust collection, enabling flexible use across multiple machines or workstations. Examples include shop vacuums for small tools and downdraft tables for independent work areas.

- Cartridge Dust Collectors: Cartridge collectors use pleated filter cartridges for high-efficiency filtration in a compact footprint. These are favored in pharmaceutical manufacturing, food processing, and electronics assembly, where space is limited and fine dust removal is paramount.

Looking for guidance on which dust collection system is best for woodworking? Or, how to choose between cyclone and baghouse dust collectors? Continue reading for detailed decision factors and expert recommendations.

Dust Collection System Accessories

To maximize the efficiency, safety, and lifespan of your dust collection system, a wide range of dust collection accessories are available to customize and enhance performance. These accessories include:

- Advanced Filters (HEPA/ULPA): High-Efficiency Particulate Air (HEPA) and Ultra-Low Penetration Air (ULPA) filters trap ultrafine particles, allergens, and hazardous dust, ensuring compliance with stringent air quality standards.

- Pre-Separators/Cyclones: These devices remove larger debris and bulk material before air reaches the main dust collector, reducing filter load and maintenance frequency.

- Blast Gates: Manual or automated blast gates control airflow, directing suction to specific machines or work areas as needed. This optimizes collection efficiency and reduces energy consumption.

- Flexible Hoses and Ducting: Essential for connecting machinery to the dust collection system, high-quality hoses and ducts minimize leaks and static buildup.

- Explosion-Proof Valves and Suppression Systems: Required in environments where combustible dust is present, these accessories help prevent ignition and contain explosions.

- Dust Collection Bags and Bins: Available in disposable and reusable formats, collection bags and bins facilitate easy disposal of captured material.

- Monitoring and Automation Controls: Advanced control panels, sensors, and remote monitoring systems allow for real-time performance tracking, filter status alerts, and automated cleaning cycles.

Beyond improving air quality and performance, dust collection system accessories also contribute to worker safety and health by reducing airborne dust and associated risks. This is especially critical in industries such as woodworking, metalworking, construction, pharmaceuticals, and food manufacturing, where dust and debris are prevalent. Additionally, with increasing regulatory scrutiny on air quality and emissions, the right accessories help companies comply with OSHA, EPA, and NFPA standards, preventing costly fines or shutdowns.

Accessories can also extend the operational life of your main dust collector by reducing wear and tear, improving energy efficiency, and minimizing downtime for maintenance. Efficiently maintained systems require less frequent and less expensive repairs, saving time and money. If you’re searching for where to buy dust collector accessories or how to upgrade your existing dust collection system, consider reputable home improvement stores, specialty woodworking shops, authorized online retailers, and direct-from-manufacturer channels. For high-volume or specialized industrial applications, industrial equipment suppliers and OEMs offer tailored solutions and expert support.

In summary, dust collection system accessories are vital for enhancing collection efficiency, ensuring safety and regulatory compliance, protecting worker health, and extending equipment lifespan. Understanding the available options and sourcing the best accessories will help you achieve optimal results for your facility.

Industries That Use Dust Collecting Systems

Dust collection systems are essential across a vast array of industries that generate airborne particulates, fumes, and dust during their processes. These systems are a key element of modern industrial hygiene and workplace safety programs. Here are some of the most common industries and their unique dust control challenges:

- Cement Production: Dust collectors manage cement kiln emissions and raw material handling, preventing fine cement dust from contaminating the air.

- Mining & Quarrying: High-capacity dust extraction systems capture dust from crushing, conveying, and screening operations, improving air quality and protecting worker health.

- Metal Fabrication & Steel Mills: Capture grinding dust, welding fumes, plasma cutting emissions, and metallic particulates, preventing equipment fouling and complying with workplace exposure limits.

- Woodworking & Sawmills: Collect sawdust, wood chips, and sanding debris from cutting, planing, and shaping, reducing combustible dust hazards and maintaining a clean workspace.

- Recycling Facilities: Control dust generated during sorting, shredding, and baling of recyclable materials, improving environmental health and regulatory compliance.

- Pulp & Paper: Remove fine paper fibers and dust to prevent fire risks and ensure product quality during paper manufacturing.

- Automotive & Aerospace: Dust collectors extract sanding, painting, and finishing dust, as well as hazardous fumes from composite materials and adhesives.

- Glass & Ceramics Manufacturing: Capture silica dust and fine particulates that can cause silicosis and equipment wear.

- Pharmaceutical & Medical Manufacturing: Maintain cleanroom conditions and control powder dispersion during tablet pressing, blending, and packaging.

- Food & Beverage Processing: Dust extraction systems manage flour dust, sugar, spices, and other food particulates, reducing cross-contamination and supporting FDA compliance.

- Construction & Demolition: Portable dust collectors manage dust from concrete cutting, drilling, and surface preparation, protecting workers and reducing site contamination.

- Plastics, Rubber, and Chemical Processing: Control dust and fumes from compounding, conveying, and molding operations, supporting product quality and environmental safety.

Overall, dust collection systems are indispensable across sectors including cement fabrication, metalworking, mining, woodworking, recycling, agriculture, automotive, construction, pharmaceuticals, medical, glass production, and more. By capturing and containing airborne dust and particles, these systems protect worker health, improve plant cleanliness, reduce fire and explosion risks, and support compliance with environmental and occupational safety regulations. Interested in industry-specific dust collection solutions or how dust collectors can boost your productivity? Contact a trusted manufacturer for a tailored assessment and recommendations.

Care and Upkeep

Proper care, maintenance, and upkeep of dust collection systems are essential to ensure their optimal performance and maximize equipment lifespan. Regular maintenance not only preserves air quality and safety but also prevents unplanned downtime and costly repairs. Here are best practices for dust collector maintenance:

- Follow Manufacturer Guidelines: Always consult the OEM’s manual for specific maintenance schedules, cleaning intervals, lubrication instructions, and recommended spare parts.

- Routine Inspections: Conduct monthly or weekly inspections depending on system usage. Check for leaks, damaged ductwork, clogged filters, and proper fan operation.

- Filter and Bag Replacement: Clean or replace filters and collection bags every three to six months for standard use. High-demand operations may require more frequent attention. Use filter performance monitors to track pressure drop and predict replacement intervals.

- Empty Collection Bins: Empty bins or hoppers based on dust accumulation—this may range from daily (in high-volume applications) to monthly (for lighter use).

- Lubrication: Lubricate moving parts, such as fan bearings and shaker mechanisms, per manufacturer recommendations—typically every few months or annually.

- Monitor System Performance: Install pressure gauges, airflow meters, and differential pressure sensors to detect performance issues early.

- Professional Service: Schedule annual or semi-annual service checks by certified technicians for large or mission-critical systems.

Proactive maintenance reduces the risk of filter blinding, system inefficiency, and unplanned breakdowns—helping you maintain workplace safety and regulatory compliance. If you notice declining performance, increased dust emissions, or system alarms, increase the frequency of inspections and consider professional troubleshooting. For more information on how to properly maintain a dust collection system or how to diagnose dust collector issues, consult your manufacturer or a qualified service provider.

Considerations When Choosing a Dust Collector

Choosing the right industrial dust collection system is critical for effective air quality management and regulatory compliance. The best results are achieved when the dust collector is integrated into a comprehensive air quality control strategy, which may include air scrubbers, make-up air units, and local exhaust ventilation. Selecting a supplier with industry expertise, high-quality products, and excellent customer support is essential for long-term success.

When evaluating dust collection systems for purchase or upgrade, consider these key decision factors:

- Dust Type and Properties: The size, shape, and chemical reactivity of dust determine the appropriate collector and filter media. For example, synthetic cellulose filters are effective for dry, fine dust, while spun-bond polyester filters handle moist, sticky, or oily dust. For hazardous dust, HEPA or ULPA filtration may be required.

- Air Volume and Velocity: A dust collector must move sufficient air—measured in cubic feet per minute (cfm)—at the correct speed (feet per minute, fpm) to capture and transport dust from the point of origin. Different machines and processes have specific cfm requirements. For example, table saws may require 350–400 cfm, while large CNC routers need 1000+ cfm.

- Duct Design and Static Pressure: The size, layout, and material of the ductwork affect airflow and system efficiency. Static pressure—frictional resistance within the duct—must be calculated accurately to select the correct fan and ensure system performance.

- Central vs. Portable Systems: Central dust collection systems are ideal for large-scale, permanent installations requiring high vacuum power and space efficiency. Portable dust collectors are cost-effective, flexible, and easy to move, making them suitable for smaller workshops or mobile job sites.

- Filtration Efficiency and Regulatory Compliance: Depending on local, state, or federal regulations, you may need to meet specific particulate emission limits. High-efficiency filters, explosion-proof features, and spark arrestors may be required for certain industries (e.g., pharmaceuticals, food processing, metalworking).

- Maintenance and Operating Costs: Factor in filter replacement frequency, energy consumption, required maintenance, and spare parts availability. Automated filter cleaning, pre-separators, and monitoring systems can reduce total cost of ownership.

- System Scalability and Flexibility: Consider whether the system can be expanded or reconfigured as your facility grows or production needs change.

It’s important to remember that even the most advanced dust collection systems cannot always achieve 100% efficiency. If your application is highly sensitive or subject to strict emissions standards, consider installing a secondary auxiliary filtration system for added protection.

Recirculating filtered air back into your facility can offer substantial benefits, including lower HVAC costs and improved energy efficiency, while still maintaining compliance with emission regulations. Explore whether this is an option for your plant by consulting with your dust collection system provider.

Ready to compare dust collector models, features, and pricing? Or wondering how much does it cost to install a dust collection system? Contact leading manufacturers, request quotes, or use our manufacturer listings to find the best solution for your needs.

Frequently Asked Questions about Dust Collection Systems

- How do I determine the right size dust collector for my shop or facility? Calculate the total cfm requirement for all machines and consider future expansion. Consult with a system designer if needed.

- What types of dust are considered hazardous, and how does this affect system design? Combustible dust, silica, asbestos, lead, and pharmaceutical powders require special filters and explosion-proof features.

- Can I retrofit my old dust collection system with new filters or accessories? Yes, many systems are designed for upgrades. Check compatibility with your manufacturer or a qualified supplier.

- How often should I schedule professional maintenance for my dust collector? At least annually for most systems; more frequently for mission-critical or high-use environments.

- How can I ensure compliance with OSHA, NFPA, and EPA regulations? Work with an experienced dust collection supplier who understands current standards and can help with system design and documentation.

For more in-depth answers or specific recommendations, visit our dust collecting system manufacturers directory or reach out to industry experts for a personalized consultation.

Dust Collector-Quality Air Management

Dust Collector-Quality Air Management

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services